Table of Contents

Understanding HEZER’s Papermaking Technology

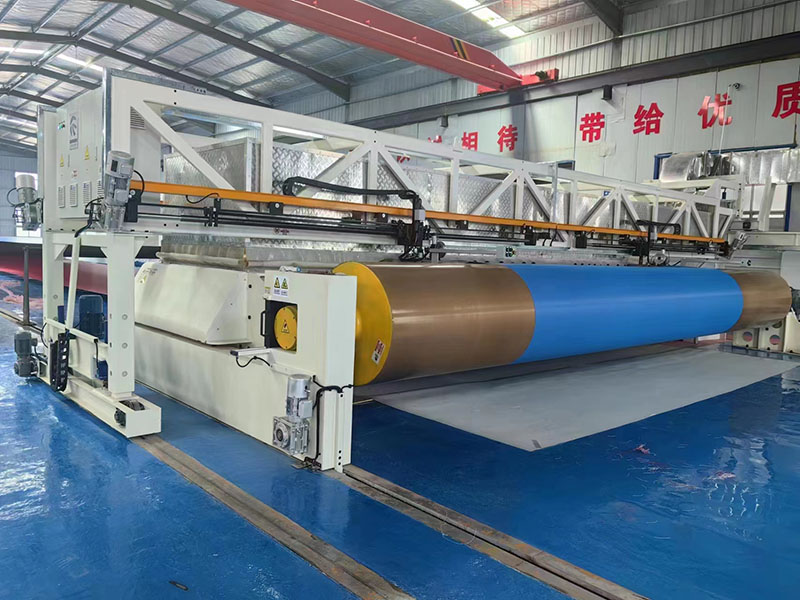

HEZER’s engineering focuses on integrated papermaking technology that enhances the physical and mechanical performance of the entire production line. Each machine is tailored for specific grades of paper—tissue, kraft, board, or specialty—and optimized with advanced control systems to reduce waste, energy consumption, and operational interruptions.

Whether you’re producing lightweight paper or heavyweight board, HEZER provides cutting-edge paper production machines to meet evolving market demands.

Learn more about HEZER’s approach

Core Benefits of HEZER Paper Making Machines

HEZER’s paper manufacturing equipment offers numerous advantages:

✅ Enhanced Productivity

By integrating modular components and real-time monitoring, HEZER machines can boost paper output by up to 30%.

✅ Superior Sheet Quality

Optimized control over fiber alignment and water drainage leads to higher formation uniformity and surface smoothness.

✅ Reduced Energy Consumption

HEZER machines are equipped with efficient press and dryer sections, minimizing steam and electricity use.

✅ Easy Maintenance

Quick-change systems and corrosion-resistant designs reduce downtime during part replacement.

✅ Compatibility with Advanced Machine Clothing

HEZER’s systems are built to maximize the benefits of forming fabrics, press felts, and dryer screens.

HEZER’s Product Categories

HEZER manufactures a full range of paper making machines, each optimized for different applications:

| Machine Type | Key Use Case | Production Speed | Paper Grades |

|---|---|---|---|

| Fourdrinier Machines | High-speed production of tissue & writing paper | 300–1500 m/min | Tissue, Writing, Printing |

| Cylinder Mould Machines | Durable and thicker papers | 100–600 m/min | Kraft, Duplex Board |

| Twin-Wire Formers | High-precision, smooth surface paper | 800–2000 m/min | Coated, Specialty Grades |

See HEZER’s full paper machine product range.

Why Paper Machine Clothing Matters

No paper manufacturing equipment is complete without the right paper machine clothing. At HEZER, we offer world-class solutions that include:

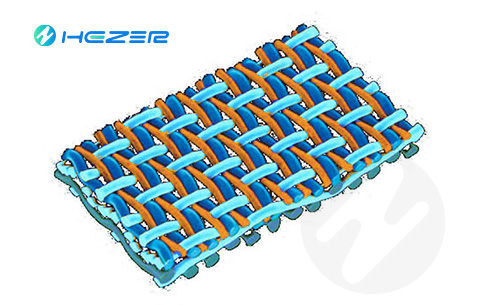

🟢 Forming Fabric

Controls water drainage and fiber orientation. Available in single, double, and triple layers.

🔗 Explore forming fabric options

🟡 Press Felt

Enhances dewatering while preserving paper sheet integrity.

🔗 View press felt series

🔴 Dryer Screen

Facilitates efficient drying and sheet transport through the dryer section.

🔗 Browse dryer screens

HEZER’s machines are designed to work seamlessly with these components for maximum operational harmony and reduced friction losses.

Efficiency and Sustainability Comparison

When compared to traditional systems, HEZER’s solutions significantly outperform on cost, speed, and energy metrics:

| Metric | Traditional Machines | HEZER Machines |

|---|---|---|

| Energy Efficiency | Moderate | High |

| Sheet Uniformity | Variable | Excellent |

| Machine Downtime | Frequent | Low |

| CO₂ Emissions per Ton | Higher | Lower |

| ROI Timeframe | >5 Years | <3 Years |

See why HEZER is the sustainable choice

How to Choose the Right HEZER Machine for Your Mill

When selecting a paper machine, consider:

-

Production Capacity

Calculate your daily tonnage and paper grade requirements. -

Fiber Type and Sourcing

Choose a machine suitable for recycled fiber or virgin pulp. -

Required GSM Range

Match your product specifications with HEZER machine capabilities. -

Machine Clothing Compatibility

Confirm alignment with HEZER’s forming fabrics, press felts, and dryer screens. -

Automation Needs

HEZER offers options with semi or full automation to match your team’s capabilities.

Need help deciding? Contact our technical support

Customer Success Case Studies

📍 Case Study: Southeast Asia Kraft Paper Plant

-

Challenge: Inconsistent GSM and frequent web breaks

-

Solution: Installed HEZER Fourdrinier Machine + triple-layer forming fabric

-

Result: +25% production efficiency, -30% downtime

📍 Case Study: European Specialty Paper Manufacturer

-

Challenge: High energy consumption in drying section

-

Solution: Switched to HEZER Dryer Section and dryer screen

-

Result: 22% reduction in steam use per ton

Where to Get Started

Whether you’re expanding operations or upgrading outdated machinery, HEZER offers complete support—from equipment selection to long-term servicing.

🔗 Browse all HEZER paper making machines

🔗 Explore machine clothing solutions

🔗 Read our company story

🔗 Contact us for a quote

FAQs

Q: Can HEZER machines be customized for specific paper grades?

A: Yes, we offer custom engineering based on GSM range, fiber mix, and production environment.

Q: Do HEZER machines support recycled paper pulp?

A: Absolutely. HEZER machines are optimized for both virgin and recycled pulp streams.

Q: How often should I replace paper machine clothing?

A: Replacement cycles vary by machine and material type, but generally every 6–12 months.

🔗 Learn more about replacement guidelines