Introduction: The Value of Proper Maintenance

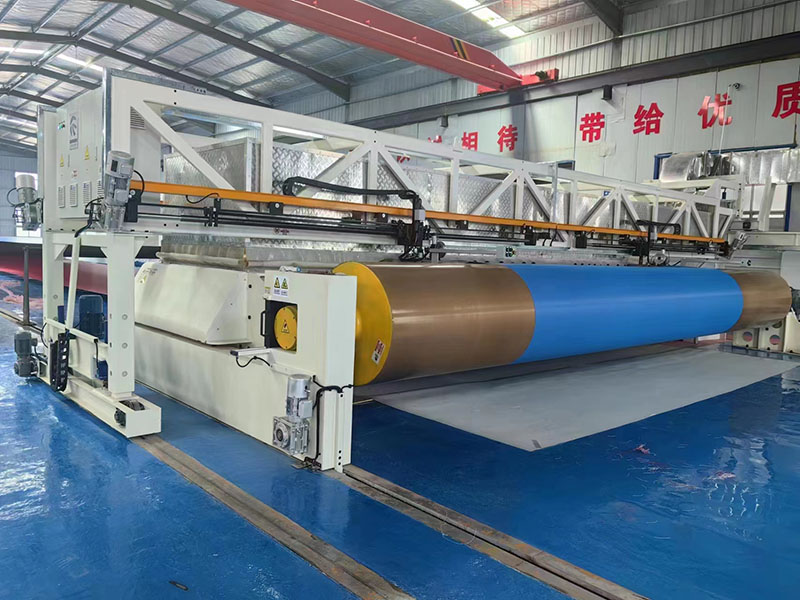

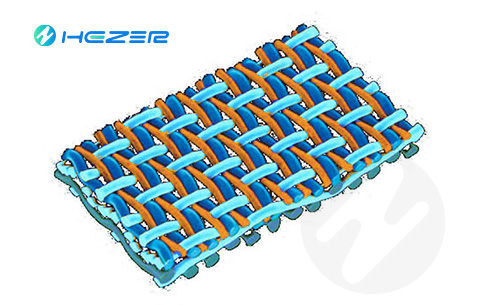

At HezeRbelt, we know that paper machine clothing represents a significant investment for any paper manufacturer. These critical components – forming fabrics, press felts, and dryer screens – can account for up to 15% of your operational costs. However, with proper maintenance practices, you can extend their service life by 30-50%, dramatically reducing replacement costs and minimizing unplanned downtime.

This comprehensive maintenance guide provides paper manufacturers with proven strategies to maximize the lifespan of their machine clothing. We’ll cover essential daily practices, periodic maintenance routines, troubleshooting techniques, and advanced care methods that collectively contribute to longer clothing life and more stable paper production.

Understanding Maintenance Impact on Clothing Lifespan

Proper maintenance directly correlates with extended service life:

Maintenance Effect on Clothing Longevity

| Maintenance Level | Expected Lifespan | Cost Impact |

|---|---|---|

| Poor | 3-6 months | High replacement costs |

| Basic | 6-12 months | Moderate costs |

| Good | 12-18 months | Reduced costs |

| Excellent | 18-24+ months | Significant savings |

Our lifespan calculator shows potential savings from improved maintenance.

Daily Maintenance Essentials

Implement these critical daily practices:

Daily Maintenance Checklist

- Visual Inspections

- Check for visible wear patterns

- Identify contamination buildup

- Spot early damage signs

- Shower System Checks

- Verify proper nozzle function

- Confirm adequate water pressure

- Ensure complete coverage

- Tension Monitoring

- Check tension consistency

- Verify tracking alignment

- Adjust as needed

- Performance Observations

- Monitor drainage patterns

- Note quality changes

- Track efficiency metrics

Download our daily maintenance log for consistent tracking.

Weekly Maintenance Routines

These weekly tasks prevent premature wear:

Weekly Maintenance Tasks

| Task | Purpose | Tools Needed |

|---|---|---|

| Detailed Fabric Inspection | Identify developing issues | Magnifying glass, flashlight |

| Shower Head Cleaning | Maintain cleaning efficiency | Nozzle cleaning tools |

| Edge Condition Check | Prevent edge-related failures | Calipers, visual inspection |

| Tension Verification | Ensure optimal settings | Tension measurement device |

| Cleaning Efficiency Test | Verify shower effectiveness | Water penetration test |

Our maintenance toolkit includes specialized tools for these tasks.

Monthly Comprehensive Maintenance

Deeper monthly care extends clothing life:

Monthly Maintenance Protocol

- Full Clothing Assessment

- Measure wear rates

- Document stretch patterns

- Record contamination levels

- System Performance Review

- Analyze drainage data

- Evaluate energy consumption

- Review quality metrics

- Preventive Actions

- Rotate fabrics if applicable

- Apply protective treatments

- Plan upcoming replacements

Schedule a professional maintenance audit for comprehensive assessment.

Proper Cleaning Techniques

Effective cleaning is the cornerstone of longevity:

Cleaning Method Comparison

| Method | Best For | Frequency | Considerations |

|---|---|---|---|

| High-Pressure Showers | Daily contamination | Continuous | Proper nozzle selection |

| Chemical Cleaning | Stubborn deposits | Weekly-Monthly | Material compatibility |

| Mechanical Cleaning | Heavy buildup | As needed | Avoid fabric damage |

| Steam Cleaning | Deep penetration | Monthly | Temperature control |

Our cleaning optimization guide provides detailed protocols.

Tension Management Best Practices

Proper tensioning prevents many common issues:

Tension Guidelines by Clothing Type

| Clothing Type | Initial Tension | Operating Tension | Maximum Allowable |

|---|---|---|---|

| Forming Fabrics | 2.5-3.5 kN/m | 3.0-4.0 kN/m | 4.5 kN/m |

| Press Felts | 3.0-4.0 kN/m | 4.0-5.0 kN/m | 6.0 kN/m |

| Dryer Fabrics | 1.5-2.5 kN/m | 2.0-3.0 kN/m | 3.5 kN/m |

Use our tension monitoring system for precise management.

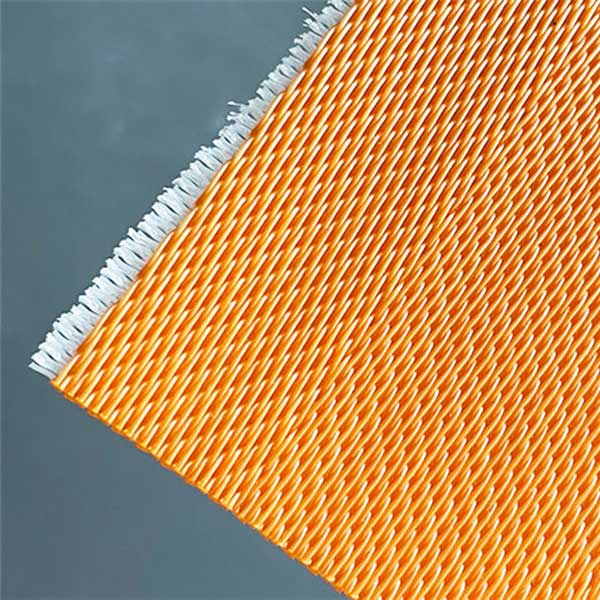

Wear Pattern Analysis and Correction

Understanding wear patterns informs maintenance:

Common Wear Patterns and Solutions

| Pattern | Likely Cause | Corrective Action |

|---|---|---|

| Edge Wear | Misalignment | Adjust guides, check rolls |

| Center Wear | Excessive tension | Reduce to recommended levels |

| Diagonal Wear | Tracking issues | Correct roll alignment |

| Random Patches | Contamination | Improve cleaning regimen |

| Uniform Wear | Normal aging | Plan replacement |

Our wear analysis service provides professional diagnostics.

Contamination Prevention Strategies

Contaminants dramatically reduce clothing life:

Contamination Source Control

- Stock Preparation

- Improve screening

- Optimize cleaning

- Control additives

- Water Systems

- Maintain filters

- Control microbiological growth

- Manage chemistry

- Machine Environment

- Reduce airborne contaminants

- Control oil/lubricant leaks

- Maintain clean work areas

Implement our contamination control program for cleaner operation.

Seasonal Maintenance Considerations

Adjust maintenance for changing conditions:

Seasonal Maintenance Adjustments

| Season | Challenges | Maintenance Focus |

|---|---|---|

| Summer | High humidity | Microbial control, drying efficiency |

| Winter | Low temperatures | Condensation management, stiffness |

| Monsoon | Moisture fluctuations | Drainage optimization, tracking |

| Dry Seasons | Static electricity | Anti-static measures, humidity control |

Our seasonal maintenance guide provides detailed recommendations.

Advanced Maintenance Technologies

Modern tools enhance maintenance effectiveness:

Maintenance Technology Options

- Automated Monitoring Systems

- Continuous tension tracking

- Real-time wear monitoring

- Predictive analytics

- Advanced Cleaning Systems

- Self-optimizing showers

- Targeted chemical injection

- Rotating nozzle designs

- Diagnostic Tools

- Digital microscopy

- Surface profilometers

- Material testing devices

Explore our maintenance technology solutions.

Training Your Team for Maintenance Success

Skilled personnel are essential for proper care:

Maintenance Training Program Outline

- Basic Training

- Daily inspection techniques

- Routine cleaning procedures

- Basic troubleshooting

- Advanced Skills

- Wear pattern interpretation

- Tension optimization

- Contamination analysis

- Specialized Knowledge

- Grade change procedures

- Fabric repair techniques

- Performance optimization

Enroll your team in our maintenance certification program.

Documentation and Record Keeping

Systematic tracking improves maintenance:

Essential Maintenance Records

- Daily Logs

- Visual inspection notes

- Performance observations

- Cleaning schedule

- Measurement Records

- Tension data

- Wear measurements

- Thickness profiles

- Event Documentation

- Break records

- Repair history

- Replacement dates

Use our digital maintenance tracking system for comprehensive records.

When to Repair vs. Replace

Making cost-effective decisions:

Replacement Decision Matrix

| Condition | Action | Considerations |

|---|---|---|

| <10% wear | Continue use | Monitor regularly |

| 10-30% wear | Repair if possible | Cost-benefit analysis |

| 30-50% wear | Plan replacement | Lead time considerations |

| >50% wear | Immediate replacement | Downtime costs |

Our replacement advisory service provides objective recommendations.

Conclusion: The Maintenance-Longevity Connection

Effective maintenance of paper machine clothing isn’t just about preserving equipment—it’s a strategic approach to reducing operational costs, improving paper quality, and maximizing production efficiency. By implementing the comprehensive maintenance practices outlined in this guide, paper manufacturers can significantly extend clothing lifespan, often achieving 30-50% longer service periods compared to minimally maintained installations.

At HezeRbelt, we combine high-performance paper machine clothing with expert maintenance support to deliver complete solutions for our customers. Our technical team can help you develop a customized maintenance program tailored to your specific machine configuration, paper grades, and operational requirements.

Ready to extend your clothing lifespan and reduce operating costs? Contact our maintenance experts today or explore our range of long-life clothing solutions. Let’s work together to optimize your maintenance practices and achieve new levels of cost-effective paper production.