Introduction

In industrial applications, especially in papermaking and sewage treatment, dryer fabrics are essential materials used to ensure efficient drying processes. These fabrics play a critical role in speeding up drying time, improving product quality, and enhancing energy conservation. Whether you are producing paper or working in the textile industry, selecting the right dryer fabric can significantly influence your production process and outcomes.

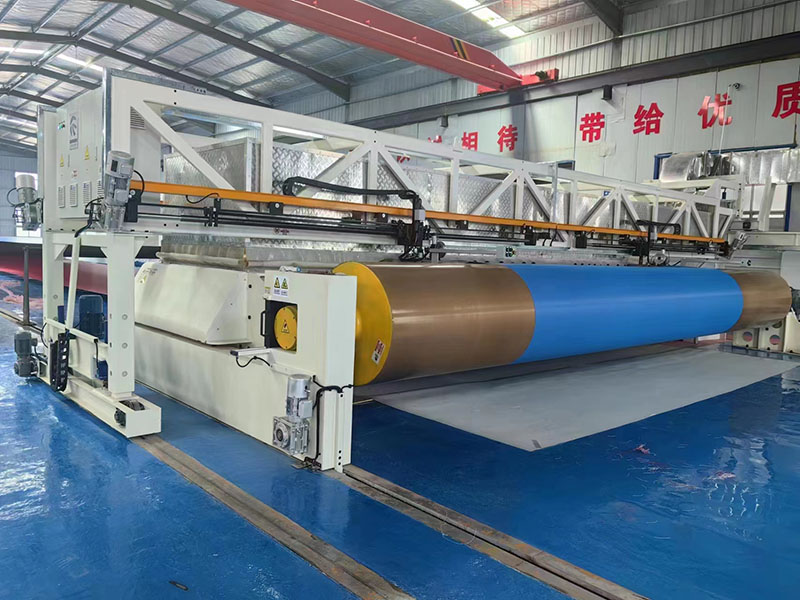

As a leading dryer fabric supplier in China, Hezer provides top-of-the-line products designed for high performance and durability. Our dryer fabrics are engineered to improve drying efficiency, reduce energy consumption, and ensure the smooth operation of industrial machinery.

In this blog, we will explore the various features and benefits of dryer fabrics, including the difference between Spiral Dryer Fabrics and Woven Dryer Fabrics. We will also discuss how these fabrics contribute to better drying, higher paper quality, and energy savings in various industries.

What are Dryer Fabrics?

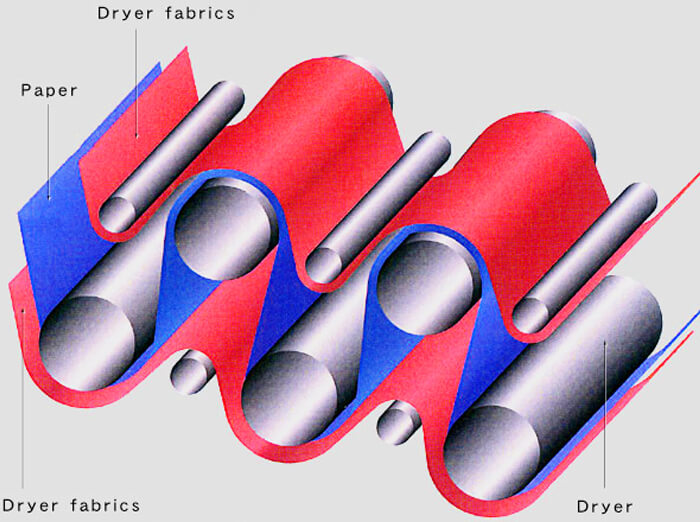

Dryer fabrics are specialized textiles used in various industries to facilitate the drying process. In papermaking, these fabrics are used in the dryer section of the paper machine to aid in the removal of moisture from the paper web. In sewage treatment, dryer fabrics help in the efficient drying of sludge and other materials.

Hezer’s dryer fabrics come in different types, including Spiral Dryer Fabrics and Woven Dryer Fabrics, each designed to meet the specific needs of different industrial applications.

Key Features of Hezer Dryer Fabrics

-

High Contact Surface Area and Efficient Heat Transfer

The primary function of dryer fabrics is to provide an optimal surface for heat transfer. Hezer’s dryer fabrics are designed with a high contact surface area that ensures efficient heat transfer, speeding up the drying process. This improves productivity by reducing drying time. -

Excellent Dimensional Stability

Dimensional stability is crucial in ensuring that dryer fabrics maintain their shape and structure throughout their use. Hezer’s dryer fabrics are made from durable materials that resist shrinking or stretching, ensuring consistent performance over time. -

Excellent Wear Resistance and Clogging Resistance

One of the key challenges in the drying process is fabric wear and clogging. Hezer’s dryer fabrics are designed to withstand the mechanical stresses of continuous use and are resistant to clogging. This results in improved durability and longer service life, reducing maintenance costs for industrial operations. -

High Fatigue Resistance

Dryer fabrics are subjected to continuous mechanical stress, which can lead to fatigue and premature failure in lower-quality fabrics. Hezer’s fabrics are engineered to resist fatigue, ensuring they maintain their functionality over an extended period, even in high-stress applications. -

Easy to Clean and Maintain

Maintenance is an essential aspect of ensuring the longevity and effectiveness of dryer fabrics. Hezer’s dryer fabrics are designed for easy cleaning, reducing downtime and maintenance efforts. This feature makes them a preferred choice for industries that require high uptime. -

Efficient Drying and Runnability

Hezer’s dryer fabrics are specifically designed for efficient drying, ensuring optimal moisture removal. The fabrics also provide smooth runnability, preventing wrinkles and ensuring consistent drying performance throughout the production process. -

Medium to High Breathability

The breathability of dryer fabrics is essential for ensuring that air and moisture pass through the fabric efficiently. Hezer’s fabrics are designed with medium to high breathability, which aids in the drying process and helps maintain high-quality products.

Types of Dryer Fabrics from Hezer

Hezer manufactures two primary types of dryer fabrics: Spiral Dryer Fabrics and Woven Dryer Fabrics. Each type offers unique advantages based on specific industrial needs.

1. Spiral Dryer Fabrics

Spiral dryer fabrics are a popular choice in industries where high-speed drying and excellent moisture removal are crucial. These fabrics are constructed using a continuous spiral design, providing enhanced durability and flexibility.

Key Benefits of Spiral Dryer Fabrics:

-

Durability: Spiral designs offer increased durability, reducing fabric wear.

-

High Efficiency: These fabrics ensure efficient moisture removal, speeding up the drying process.

-

Smooth Surface: The continuous spiral design prevents fabric wrinkles and ensures smooth product output.

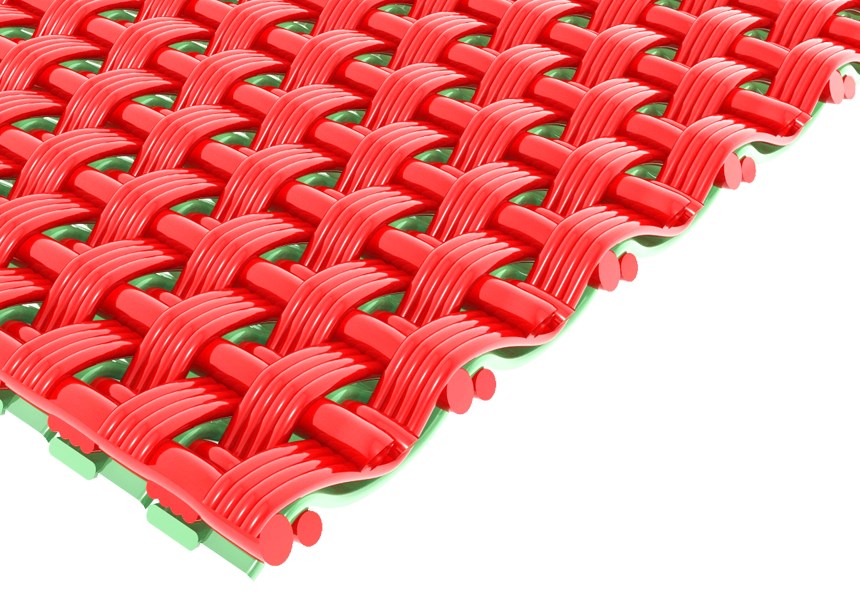

2. Woven Dryer Fabrics

Woven dryer fabrics are made by interlacing yarns in a specific pattern to create a strong and durable fabric. These fabrics are ideal for applications that require high strength and structural integrity.

Key Benefits of Woven Dryer Fabrics:

-

High Strength: Woven fabrics offer superior strength, making them ideal for heavy-duty industrial applications.

-

Even Drying: These fabrics provide uniform drying across the entire surface of the paper or material.

-

Versatility: Woven fabrics are adaptable to a wide range of drying applications, including both high and medium-speed machines.

How Dryer Fabrics Improve Drying Efficiency and Quality

In industries such as papermaking, efficient drying is essential to ensuring high-quality products. Dryer fabrics help improve drying efficiency in several ways:

1. Faster Drying Time

Hezer’s dryer fabrics are designed to optimize heat transfer, which reduces the time needed to dry the paper or material. Faster drying not only improves productivity but also helps to reduce energy consumption, which is crucial for manufacturers looking to cut costs and improve energy efficiency.

2. Higher Paper Quality

Using the right dryer fabrics ensures that the paper is dried evenly, reducing the risk of defects such as wrinkles, creases, or uneven thickness. With Hezer dryer fabrics, paper mills can consistently produce high-quality paper with a smooth surface, making them ideal for printing and other applications.

3. Energy Conservation

Hezer’s fabrics are designed to provide efficient heat transfer, which minimizes the amount of energy required for the drying process. This leads to significant energy savings, making Hezer’s dryer fabrics an environmentally friendly option for manufacturers looking to reduce their energy consumption.

4. Increased Production Efficiency

Hezer’s dryer fabrics help ensure smooth runnability and reliable performance, reducing downtime and maintenance needs. This increases the overall efficiency of production lines and helps manufacturers meet production targets.

Comparison Table: Spiral vs. Woven Dryer Fabrics

| Feature | Spiral Dryer Fabrics | Woven Dryer Fabrics |

|---|---|---|

| Durability | High durability, flexible design | Very strong, ideal for heavy-duty use |

| Drying Efficiency | High, excellent moisture removal | Good, provides even drying |

| Strength | Moderate, suitable for lighter applications | High, ideal for demanding industrial processes |

| Surface Quality | Smooth, prevents wrinkles | Even drying, reduces product defects |

| Application | High-speed drying, papermaking | Heavy-duty applications, textiles |

Why Choose Hezer for Your Dryer Fabrics?

Hezer is a trusted supplier of high-quality dryer fabrics for industrial applications. Our fabrics are designed for high performance, durability, and efficiency. Whether you need Spiral Dryer Fabrics or Woven Dryer Fabrics, Hezer provides customized solutions tailored to your production requirements.

We understand the importance of reliable dryer fabrics in achieving high-quality products and efficient production. That’s why our fabrics are trusted by manufacturers across a wide range of industries, from papermaking to sewage treatment.

Explore our full range of dryer fabrics and find the perfect solution for your industrial needs by visiting our dryer fabrics product page.