In industries such as filtration, dewatering, and drying, the quality of the materials used in the process directly influences the efficiency and effectiveness of the operation. One of the key components in these processes is the industrial filter belt. A reliable and durable filter belt can significantly improve the performance and longevity of the equipment, reduce downtime, and enhance product quality.

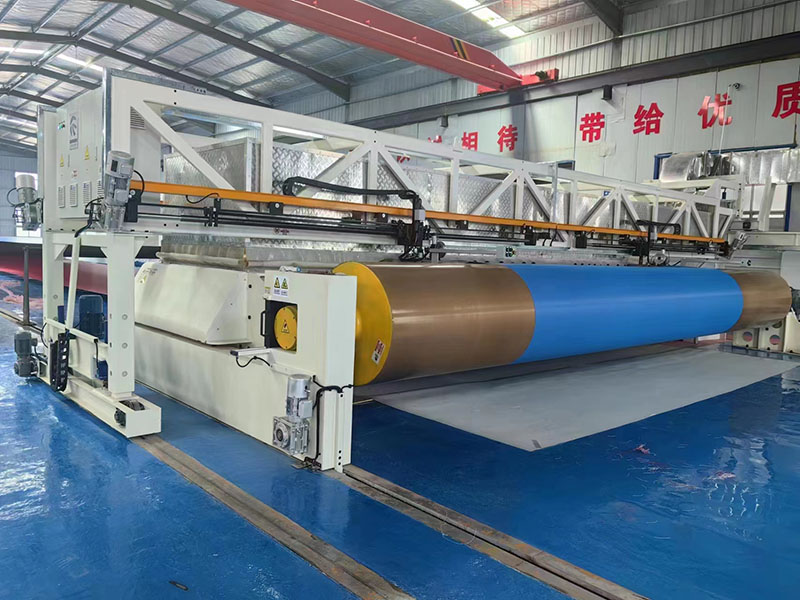

Hezer is a leading manufacturer of high-quality industrial filter belts that are trusted by industries worldwide for their exceptional durability, wear resistance, and operational reliability. Our filter belts are designed for a variety of applications, including filtration, dewatering, and drying. With advanced engineering and high-performance materials, Hezer filter belts provide unmatched reliability and efficiency in the most demanding industrial environments.

In this blog, we will explore the key features of industrial filter belts, the benefits they provide, and why Hezer’s filter belts are the best choice for industrial applications.

What Are Industrial Filter Belts?

Industrial filter belts are woven fabrics that are used in various filtration, dewatering, and drying processes. These belts play a crucial role in separating solids from liquids or gases and in transferring materials through various stages of production. They are commonly used in industries such as mining, papermaking, textiles, and chemical processing.

Hezer’s industrial filter belts are engineered to offer long-lasting performance, high filtration efficiency, and ease of maintenance. Our filter belts are designed to withstand the harsh conditions of industrial environments, including high temperatures, abrasive wear, and exposure to chemicals.

Key Features of Hezer Industrial Filter Belts

-

Long Service Life and Excellent Fabric Stability

One of the key advantages of Hezer’s industrial filter belts is their long service life. Made from high-quality materials, these belts are designed to endure continuous operation, offering excellent fabric stability. This stability ensures that the belts maintain their structural integrity over time, reducing the frequency of replacements and maintenance, which can significantly lower operational costs.

-

Wear-Resistant Design

Wear resistance is essential for any industrial belt, especially in environments where abrasive materials and harsh conditions are common. Hezer’s filter belts are designed with wear-resistant properties that ensure their durability in demanding applications. Whether used in filtration, dewatering, or drying, our belts are built to withstand friction and stress, offering reliable performance throughout their service life.

-

Extremely Strong Edge Treatment

Hezer’s industrial filter belts feature strong edge treatments that help prevent damage to the edges of the belt during operation. This edge reinforcement improves the belt’s overall durability and prevents issues such as fraying or tearing, which can lead to costly downtime and maintenance.

-

Best Drainage Performance

Efficient drainage is crucial in processes such as dewatering and filtration. Hezer’s filter belts are designed to provide optimal drainage, ensuring that liquids are removed quickly and efficiently. This results in faster processing times, improved throughput, and higher quality products.

-

Operational Reliability

Hezer’s filter belts are known for their operational reliability. Whether they are used in high-speed industrial settings or in environments with extreme temperatures and pressure, our belts perform consistently without failure. This reliability ensures that operations run smoothly, reducing the risk of downtime and improving overall production efficiency.

-

High Temperature Resistance

In many industrial applications, high temperature resistance is essential. Hezer’s industrial filter belts are designed to withstand high temperatures, making them ideal for drying and dewatering processes that involve hot materials or steam. The ability to maintain their integrity under heat ensures that these belts can be used in a wide range of demanding environments.

Why Choose Hezer’s Industrial Filter Belts?

Choosing the right filter belt for your industrial applications is crucial to ensuring efficient operations and high-quality output. Hezer offers high-performance industrial filter belts that are designed to meet the needs of various industries. Below, we’ll look at some of the specific benefits our filter belts provide.

1. Improved Filtration Efficiency

Hezer’s industrial filter belts are designed for optimal filtration efficiency. Their fine weave and superior fabric stability ensure that they provide high-quality filtration, removing contaminants from liquids and gases with precision. The excellent drainage properties allow for quicker separation of solids, leading to more efficient filtration and dewatering processes.

2. Enhanced Dewatering Performance

In industries such as mining and papermaking, dewatering is a critical process. Hezer’s filter belts excel at efficiently separating water from solid materials, ensuring that the dewatering process is quick and effective. This enhances productivity and helps reduce operational costs associated with excessive water content in materials.

3. Reduced Maintenance and Downtime

The wear-resistant design and strong edge treatment of Hezer’s filter belts mean less frequent replacements and less maintenance. As a result, your equipment will experience fewer breakdowns and less downtime, which leads to higher overall productivity and cost savings in the long term.

4. Energy Efficiency and Cost Savings

The superior drainage performance of Hezer’s industrial filter belts reduces the energy required to process materials. The faster drying and dewatering processes reduce energy consumption, contributing to a more energy-efficient production process. This can result in significant cost savings over time, making Hezer’s filter belts a cost-effective investment for any industrial operation.

Types of Industrial Filter Belts from Hezer

Hezer manufactures a range of industrial filter belts designed to meet the specific needs of various industries. Some of the most popular types of filter belts we offer include:

1. Woven Filter Belts

Woven filter belts are made from high-quality synthetic fibers that provide excellent strength and stability. These belts are ideal for high-speed filtration and dewatering applications.

Benefits of Woven Filter Belts:

-

High strength and durability

-

Excellent resistance to wear and heat

-

Superior filtration and drainage performance

2. Spiral Filter Belts

Spiral filter belts feature a continuous spiral design that offers increased flexibility and durability. These belts are used in industries that require fast filtration and drying processes.

Benefits of Spiral Filter Belts:

-

Flexibility and easy handling

-

High filtration capacity

-

Long service life in demanding conditions

3. Nonwoven Filter Belts

Nonwoven filter belts are designed for applications where high filtration efficiency and durability are required. These belts are ideal for use in industries such as textiles, papermaking, and chemical processing.

Benefits of Nonwoven Filter Belts:

-

Excellent filtration and drainage

-

High resistance to chemicals and wear

-

Long-lasting performance

Comparison Table: Types of Hezer Filter Belts

| Feature | Woven Filter Belts | Spiral Filter Belts | Nonwoven Filter Belts |

|---|---|---|---|

| Strength | High | Moderate to High | High |

| Durability | Very durable, suitable for high-speed use | Flexible, suitable for fast processing | Highly durable, long service life |

| Filtration Efficiency | High | Moderate to High | Very High |

| Heat Resistance | Good | Excellent | Good |

| Chemical Resistance | Moderate | Good | Excellent |

Why Choose Hezer for Your Industrial Filter Belts?

Hezer offers the best quality industrial filter belts for a variety of industrial applications. Our products are designed with durability, efficiency, and reliability in mind, ensuring that your operations run smoothly and efficiently. We provide tailored solutions for filtration, dewatering, and drying, helping industries optimize their processes and reduce costs.

For more information about our industrial filter belts and to explore our full range of products, visit our filter belts product page.