Introduction: The Critical Link Between Clothing and Paper Quality

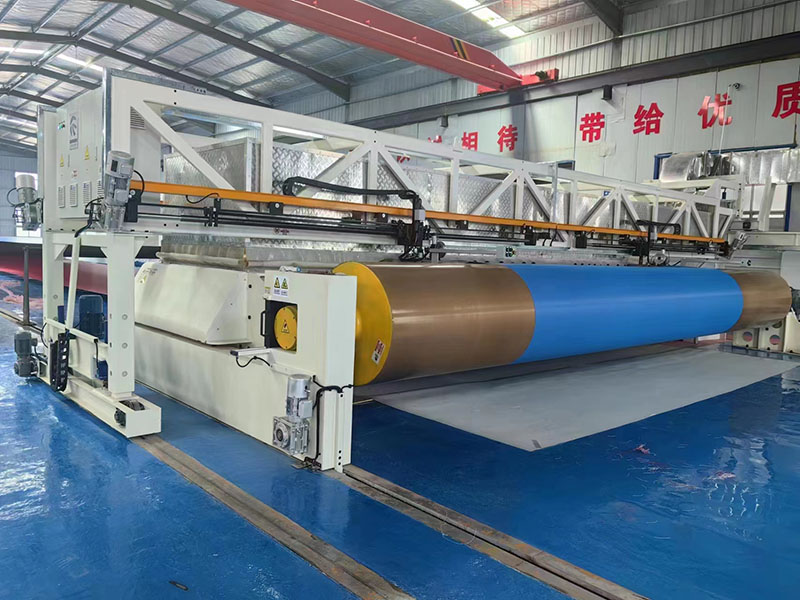

At HezeRbelt, we understand that paper machine clothing serves as the foundation for producing high-quality, consistent paper products. These essential components – forming fabrics, press felts, and dryer screens – act as the paper’s support system throughout the manufacturing process, directly influencing nearly every quality parameter. From formation uniformity to surface characteristics, the right machine clothing makes the difference between premium paper and substandard product.

This comprehensive guide examines how each type of paper machine clothing impacts various quality aspects, common quality issues related to clothing, and how to select optimal fabrics for your specific quality requirements. Whether you produce packaging materials, printing papers, or specialty products, understanding these relationships will help you achieve better consistency and quality in your paper production.

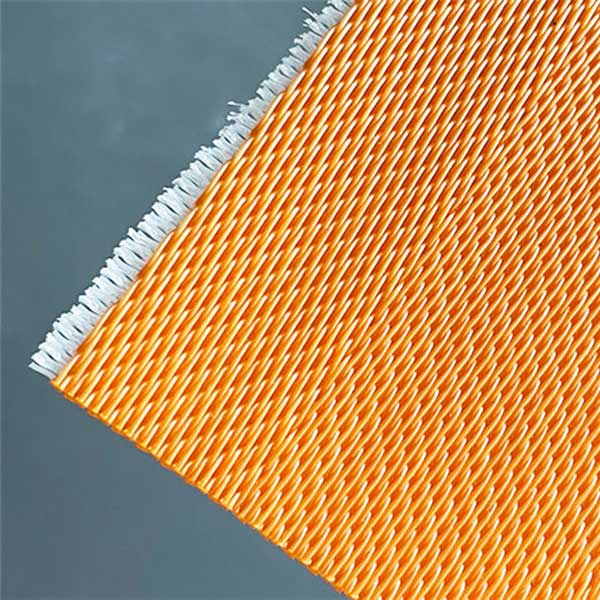

The Quality Impact of Forming Fabrics

Forming fabrics play the most crucial role in establishing the paper’s fundamental structure:

Key Quality Parameters Affected by Forming Fabrics

| Quality Parameter | How Forming Fabrics Influence It | Optimal Fabric Characteristics |

|---|---|---|

| Formation Uniformity | Controls fiber distribution | Consistent weave pattern, proper drainage |

| Two-Sidedness | Affects fiber orientation | Balanced top/bottom surface design |

| Marking | Can impart visible patterns | Appropriate weave design for grade |

| Porosity | Determines initial dewatering rate | Grade-specific permeability |

| Strength Properties | Influences fiber bonding | Proper support during formation |

Our forming fabric selection guide helps match fabrics to your quality requirements.

Press Felts and Their Role in Paper Quality

Press section felts significantly impact several critical quality metrics:

Press Felt Quality Relationships

- Density and Smoothness

- Impact: Surface characteristics

- Optimal Felt: Uniform batt distribution, smooth surface

- Compression Resistance

- Impact: Caliper and bulk

- Optimal Felt: High-resilience materials

- Water Removal Efficiency

- Impact: Drying uniformity

- Optimal Felt: Balanced permeability

- Contamination Resistance

- Impact: Visual defects

- Optimal Felt: Anti-fouling treatments

Explore our press felt solutions for improved paper quality.

Dryer Fabrics: The Final Quality Influence

Dryer fabrics maintain quality through the final production stage:

Dryer Fabric Quality Factors

A. Surface Contact

- Affects: Smoothness and finish

- Solution: Uniform contact patterns

B. Air Permeability

- Affects: Drying uniformity

- Solution: Grade-specific permeability

C. Stability

- Affects: Dimensional consistency

- Solution: Low-stretch materials

D. Cleanliness

- Affects: Visual defects

- Solution: Easy-clean designs

Our dryer fabric options address all these quality considerations.

Common Quality Issues and Clothing Solutions

Understanding and addressing frequent quality problems:

Quality Problem Troubleshooting Guide

| Quality Issue | Likely Clothing Cause | Corrective Action |

|---|---|---|

| Poor Formation | Worn forming fabric | Replace with proper design |

| Two-Sidedness | Uneven press loading | Balance press felts |

| Surface Marks | Contaminated clothing | Deep clean or replace |

| Moisture Streaks | Plugged dryer fabric | Improve cleaning system |

| Edge Weakness | Damaged clothing edges | Repair or replace |

Our quality troubleshooting service helps diagnose and resolve these issues.

Paper Grade-Specific Clothing Considerations

Different paper grades require specialized clothing approaches:

Grade-Specific Clothing Requirements

| Paper Grade | Key Quality Focus | Clothing Priorities |

|---|---|---|

| Packaging | Strength, bulk | High-compression felts |

| Printing | Surface, smoothness | Fine-surface fabrics |

| Tissue | Softness, bulk | Low-marking designs |

| Specialty | Unique properties | Custom fabric solutions |

| Board | Caliper, stiffness | Heavy-duty constructions |

Discover our grade-specific solutions for your products.

The Relationship Between Clothing Lifecycle and Quality

How clothing wear affects paper quality over time:

Quality Degradation Timeline

| Usage Period | Quality Impact | Maintenance Action |

|---|---|---|

| 0-30 days | Optimal quality | Monitor break-in |

| 30-60 days | Peak performance | Regular cleaning |

| 60-90 days | Slight decline | Increase inspections |

| 90+ days | Noticeable changes | Plan replacement |

Our lifecycle monitoring program helps maintain consistent quality.

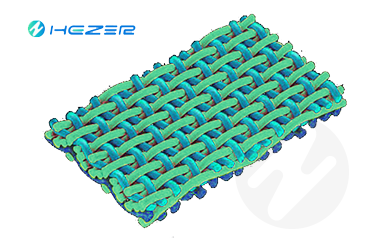

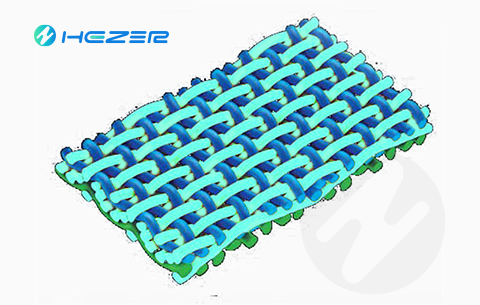

Advanced Technologies for Quality Enhancement

Innovative clothing technologies pushing quality boundaries:

Quality-Improving Technologies

- Precision Weaving

- Benefit: Exceptional formation

- Application: Critical printing grades

- Composite Structures

- Benefit: Enhanced smoothness

- Application: Premium packaging

- Smart Coatings

- Benefit: Reduced defects

- Application: Specialty papers

- Sensor-Enabled Fabrics

- Benefit: Real-time quality monitoring

- Application: High-value grades

Learn about our quality-focused innovations.

Maintaining Consistent Quality Through Proper Care

Best practices for sustaining paper quality:

Quality Maintenance Checklist

- Regular Inspections

- Daily visual checks

- Weekly detailed reviews

- Monthly comprehensive audits

- Proper Cleaning

- Optimized shower systems

- Appropriate chemical cleaning

- Scheduled deep cleaning

- Correct Operation

- Proper tensioning

- Appropriate speeds

- Grade change procedures

Download our complete quality maintenance guide.

Measuring and Quantifying Quality Improvements

Tracking clothing’s impact on paper quality:

Quality Metrics to Monitor

| Metric | Measurement Method | Clothing Influence |

|---|---|---|

| Formation | Formation analyzers | Forming fabric design |

| Smoothness | Parker Print-Surf | Press felt condition |

| Moisture | IR scanners | Dryer fabric state |

| Strength | Tensile testers | Entire clothing system |

| Defects | Vision systems | Clothing cleanliness |

Our quality analytics tools help quantify improvements.

Conclusion: Optimizing Your Quality Through Strategic Clothing Selection

Paper machine clothing represents one of the most significant yet often overlooked factors in paper quality and consistency. From the initial formation of the sheet to the final drying process, every component in the clothing system contributes to the end product’s characteristics. By understanding these relationships and selecting clothing specifically engineered for your quality requirements, you can achieve remarkable improvements in your paper’s performance.

At HezeRbelt, we combine decades of paper industry expertise with advanced manufacturing capabilities to deliver clothing solutions that enhance rather than compromise your paper quality. Our technical team works closely with customers to analyze quality challenges and recommend optimal fabric solutions tailored to specific needs.

Ready to elevate your paper quality? Contact our quality specialists today for a personalized assessment or explore our range of quality-focused products. Let’s work together to achieve the exceptional, consistent paper quality your customers demand.