Whether you are a startup paper manufacturer or a well-established industrial producer, choosing the right paper making machine is a critical investment. The right equipment not only influences your productivity and paper quality but also affects your long-term maintenance costs and scalability. In this comprehensive guide, we’ll break down the essential factors you should consider before purchasing a paper making machine. We’ll also guide you on how the right paper machine clothing, dryer screen, and press felt can optimize performance — all available from trusted suppliers like Hezerbelt.

Why the Right Paper Making Machine Matters

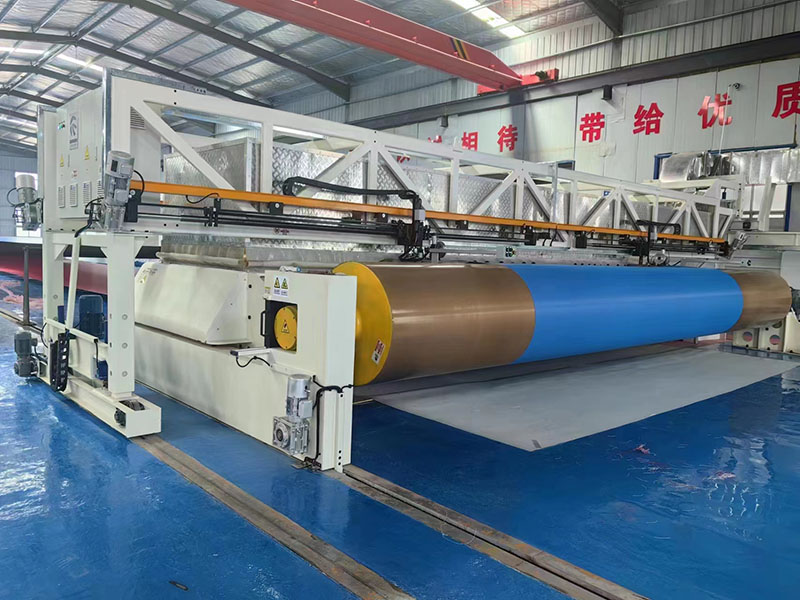

Paper manufacturing is a precise, high-capacity process that involves forming, pressing, drying, and calendaring pulp into usable paper. Each of these stages requires exact equipment configurations. Selecting a machine that aligns with your specific paper types — whether it’s kraft paper, tissue, or cardboard — determines the efficiency, product quality, and operating costs of your business.

Visit Hezerbelt’s Paper Machine Solutions to explore full-service solutions tailored for modern manufacturers.

Types of Paper Making Machines

Before diving into specifications, it’s essential to identify the type of paper you plan to produce and match it with the appropriate machine:

| Machine Type | Best For | Speed | Output Quality |

|---|---|---|---|

| Fourdrinier Machine | Fine paper, tissue paper | High | High |

| Cylinder Mould Machine | Kraft paper, cardboard | Moderate | Moderate |

| Twin-Wire Machine | Coated or specialty paper | Very High | Premium |

If you’re unsure about which type best suits your needs, consult Hezerbelt’s Machine Compatibility Guide to compare various options for dryer screens and forming fabrics.

Key Factors to Consider When Choosing a Paper Making Machine

1. Production Capacity

Consider your current and future production targets. Machines are rated in tons/day. Overestimating can lead to excess operational costs, while underestimating can cause missed deadlines and backlogs.

-

Startup companies may begin with a small Fourdrinier machine producing 5-10 TPD.

-

Large manufacturers might look at machines offering 50-100+ TPD.

Explore Hezerbelt’s press felt solutions to ensure your press section can handle high throughput without compromising quality.

2. Paper Type and Grammage

Different machines specialize in specific grammage (GSM – grams per square meter). For example:

-

Tissue paper machines operate best within 12-30 GSM.

-

Kraft and packaging machines excel in the 80-300 GSM range.

Make sure your paper machine clothing, such as forming fabrics, can handle these GSM levels with precision.

3. Drying Section Efficiency

The drying section is one of the most energy-consuming parts of a paper machine. A well-optimized dryer screen can improve thermal efficiency and reduce energy costs.

Look for:

-

Multi-cylinder drying groups

-

Steam-heated rolls with controlled ventilation

-

High-efficiency dryer screens for reduced downtime (View Hezerbelt Dryer Screens)

4. Machine Clothing and Compatibility

A high-performing machine requires reliable paper machine clothing, including:

-

Forming fabrics

-

Press felts

-

Dryer screens

Choosing high-quality consumables reduces downtime and extends machine life. Hezerbelt provides a complete range of machine clothing products engineered for various stages of the paper-making process.

5. Automation and Control Systems

Modern paper machines come with integrated PLC (Programmable Logic Controller) and SCADA systems for real-time monitoring.

Benefits of automation:

-

Lower labor costs

-

Increased accuracy

-

Fewer human errors

-

Enhanced maintenance alerts

Ensure your supplier can support automation integration and has experience with smart paper production lines.

6. Maintenance and After-Sales Support

No machine runs indefinitely without proper support. Ensure that the manufacturer or supplier provides:

-

Spare parts availability

-

Remote technical support

-

On-site service engineers

You can rely on Hezerbelt’s after-sales services for regular maintenance and troubleshooting guidance.

How Paper Machine Clothing Enhances Performance

Machine clothing isn’t just a spare part — it’s a performance driver. Each component contributes to moisture control, paper web formation, and overall machine speed.

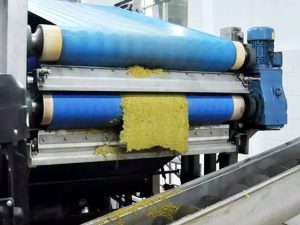

– Forming Fabric:

Responsible for paper web formation. Should have good fiber retention and drainage properties.

– Press Felt:

Removes water from the paper sheet while providing smooth surface texture.

– Dryer Screen:

Transfers the paper sheet through the drying section. Needs heat resistance and dimensional stability.

Comparing Costs: CAPEX vs. OPEX

| Cost Element | Capital Expenditure (CAPEX) | Operating Expenditure (OPEX) |

|---|---|---|

| Initial Machine Purchase | High | – |

| Machine Clothing | Medium | Recurring |

| Energy Consumption | Low | High |

| Maintenance | Medium | Recurring |

| Labor | Low | Moderate |

While initial machine cost is important, optimizing for long-term operating costs—such as energy and machine clothing replacement—is more sustainable.

Choosing the Right Supplier

When evaluating suppliers for your machine or components, assess them on:

-

Industry Experience

Does the company specialize in pulp and paper manufacturing? -

Product Range

Can they provide comprehensive solutions, such as forming fabrics, press felts, and dryer screens? -

Customization Options

Do they offer custom sizing, GSM range compatibility, and design consultation?

Hezerbelt stands out with a complete in-house production line for paper machine clothing, backed by over 20 years of industry experience.

Final Tips Before Purchase

-

Request a Sample Test: Test forming fabrics or felts under actual production conditions.

-

Inspect Machine Layout: Ensure that it fits your floor space and integrates well with existing infrastructure.

-

Look for Testimonials: A trusted supplier should be able to provide client success stories.

💡 Contact Hezerbelt for technical consultations and personalized product recommendations.