In today’s highly competitive paper manufacturing industry, production efficiency and product quality are essential to growth. One of the most effective ways to achieve both is by selecting the right paper making machine and pairing it with high-performance paper machine clothing. Whether you’re producing tissue paper, kraft paper, or specialty sheets, your equipment setup determines your ability to meet market demand while keeping operating costs in check.

This article explains how to boost your paper production by choosing the correct equipment configuration. You’ll also find practical advice on selecting forming fabric, press felt, and dryer screen from top suppliers like Hezerbelt — a trusted name in paper machine clothing solutions.

Table of Contents

Why Equipment Selection Matters

The success of a paper mill depends not just on pulp quality and labor skill but also on how well its machines are configured. A mismatched or outdated paper making machine setup can result in:

-

Increased energy consumption

-

Frequent machine downtime

-

Low-quality paper output

-

Inefficient water drainage

Optimizing your system with advanced components from Hezerbelt’s product line significantly improves performance and reduces long-term operational costs.

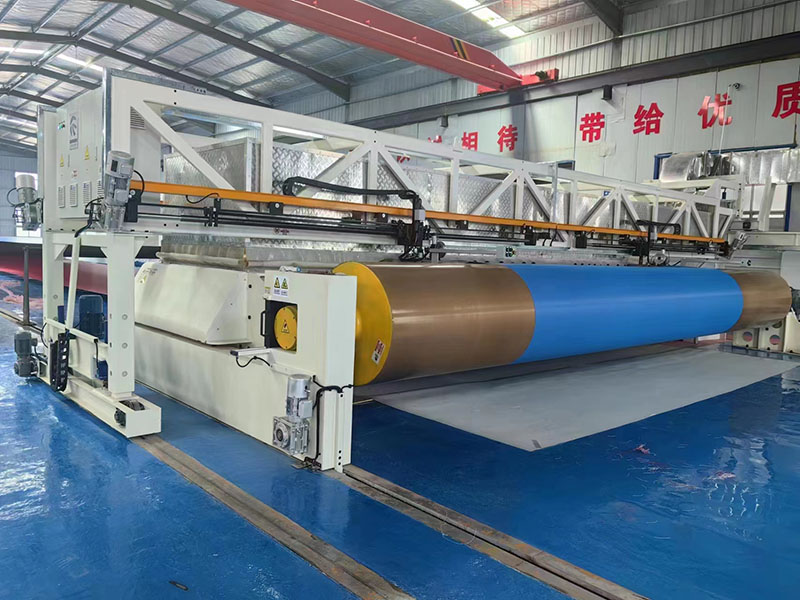

Types of Paper Making Machines

Each type of paper machine is built for a specific paper type and production speed. Below is a breakdown of the most common machines:

| Machine Type | Best For | Speed (m/min) | Paper Weight (GSM) |

|---|---|---|---|

| Fourdrinier Machine | Tissue, writing, printing | 300–1000 | 30–150 |

| Cylinder Mould Machine | Kraft paper, duplex board | 150–600 | 80–450 |

| Twin-Wire Former | Coated, high-grade papers | 800–1800 | 40–200 |

Each type requires specific machine clothing such as forming fabric, press felt, and dryer screen to ensure efficiency and durability.

Essential Components: Paper Machine Clothing

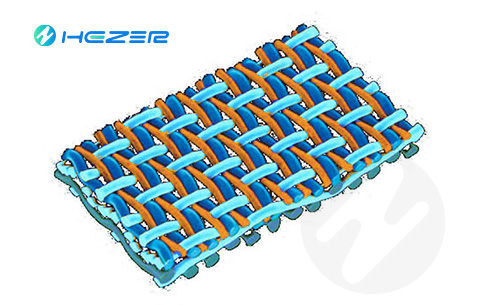

1. Forming Fabric

This is where the paper sheet is formed. A high-quality forming fabric ensures:

-

Excellent fiber retention

-

Controlled water drainage

-

Uniform sheet formation

Explore forming fabric options here

2. Press Felt

Located in the pressing section, the press felt helps remove water from the sheet and enhances paper surface properties. It also supports consistent sheet runnability and improves machine speed.

-

Long life cycle

-

Stable structure under high pressure

-

High water absorption rate

3. Dryer Screen

The dryer section consumes the most energy. A superior dryer screen enhances drying uniformity, minimizes paper breaks, and reduces steam costs.

-

Good thermal resistance

-

Long-lasting weave integrity

-

Optimized airflow

Shop Hezerbelt’s dryer screen collection

Performance Optimization Tips

To get the most out of your paper making setup, consider these optimization tactics:

A. Optimize Drainage in Forming Section

Use double-layer or triple-layer forming fabrics to enhance sheet formation and water removal.

B. Minimize Rewetting in the Press Section

Choose felts with high void volume and fast dewatering to reduce rewetting and energy loss.

C. Improve Thermal Efficiency in Drying

Hezerbelt’s dryer screens offer high air permeability and excellent heat resistance for better moisture evaporation.

D. Use Tension Control Systems

Advanced machines integrate with tension control systems that prolong the life of machine clothing and reduce breakage.

E. Schedule Regular Maintenance

Routine checks and early replacement of worn machine clothing reduce unscheduled downtime.

Cost vs. Output Analysis

Here is a breakdown comparing production costs and output improvements based on equipment optimization:

| Component | Low-End Machine Setup | Optimized Setup with Hezerbelt |

|---|---|---|

| Output Quality | Moderate | High |

| Energy Consumption | High | Reduced by 20–30% |

| Machine Downtime | Frequent | Rare with routine clothing changes |

| Lifetime of Machine Parts | Short | Extended with premium materials |

| ROI Period | >5 years | <3 years |

Choosing the Right Supplier

Partnering with a knowledgeable supplier who understands your industry needs is crucial.

What to Look for:

-

In-house production capabilities

-

Custom design services

-

Fast turnaround on orders

-

Dedicated technical support

-

20+ years of experience

-

Full catalog of machine clothing

-

Worldwide delivery

-

Industry-trusted support team

📞 Contact Hezerbelt for a consultation

Frequently Asked Questions (FAQ)

Q1: Can I use the same machine clothing for different types of paper?

A1: It’s not recommended. Each paper grade requires tailored forming fabric, press felt, and dryer screen based on grammage, moisture level, and fiber content.

Q2: How often should I replace my machine clothing?

A2: Typically every 6–12 months, depending on usage. Hezerbelt offers custom recommendations based on your production volume.

Q3: Do I need technical support to install new paper machine clothing?

A3: Yes. Proper installation ensures longevity and performance. Hezerbelt’s technical team can guide you through the process.

Conclusion and Key Takeaways

Investing in the right paper making machine and quality paper machine clothing directly impacts your profitability, product quality, and operational stability. From forming fabrics to dryer screens, each part plays a vital role in optimizing your paper production.

✅ Actionable Summary:

-

Select a machine suited to your GSM range and product type

-

Use high-quality forming fabric for clean and uniform formation

-

Optimize drying with energy-efficient dryer screens

-

Partner with experts like Hezerbelt for end-to-end support

-

Ensure regular maintenance to extend machinery life