At HEZER, we understand the complexities involved in paper production and the critical role that efficient machinery and high-quality materials play in achieving optimal results. As a leading paper manufacturer, we offer a comprehensive suite of solutions designed to support every step of the papermaking process, from the initial stages of fabric formation to the final stages of paper drying and finishing. In this blog, we’ll walk you through HEZER’s innovative papermaking fabrics, paper machine belts, and cutting-edge paper machines that work together to create seamless, high-quality paper products.

The Importance of Choosing the Right Paper Manufacturing Solutions

When it comes to paper manufacturing, every step of the process requires precision, quality, and reliability. Choosing the right paper manufacturing solutions can make a significant difference in production efficiency, paper quality, and overall costs. As a trusted paper manufacturer, HEZER focuses on delivering tailored solutions that help papermakers streamline operations while ensuring that each piece of paper meets the highest standards of durability and quality.

HEZER’s expertise lies in providing end-to-end support for papermakers. From paper machine clothing to high-performance paper machine belts, we ensure that our solutions optimize every stage of production. This holistic approach results in increased productivity, reduced downtime, and a higher return on investment (ROI).

Our Paper Manufacturing Solutions: A Comprehensive Overview

HEZER’s solutions cover a wide range of aspects within the papermaking process, including forming fabrics, dryer fabrics, filter belts, and paper making machines. Let’s explore how each of these components contributes to the success of the papermaking process:

1. Papermaking Fabrics: The Heart of the Paper Machine

At the heart of the papermaking process are papermaking fabrics, such as forming fabrics and dryer fabrics, which are essential for the smooth and efficient operation of paper machines. These fabrics are used in different parts of the paper machine to ensure the efficient transfer of paper fibers, the removal of excess water, and the creation of a smooth surface for the paper sheet.

Forming fabrics are used in the wet end of the paper machine, where they play a crucial role in shaping the paper sheet and transporting it to the next section of the machine. These fabrics are designed to be durable, water-resistant, and capable of handling high-speed operations. HEZER’s forming fabrics are engineered to reduce formation issues and help papermakers achieve a consistent, smooth paper surface.

Dryer fabrics, on the other hand, are used in the drying section of the paper machine. Their main role is to remove residual water from the paper web that could not be removed by vacuum or pressing. HEZER’s dryer fabrics are designed to provide high heat resistance and low energy consumption, ensuring faster drying times and superior paper quality.

| Type of Fabric | Function | Key Features |

|---|---|---|

| Forming Fabrics | Shaping and transporting paper sheets | High durability, water resistance |

| Dryer Fabrics | Drying the paper sheet after water removal | Heat resistance, energy efficiency |

2. Paper Machine Belts: Essential for Optimizing Papermaking

HEZER’s paper machine belts play an essential role in improving the efficiency and performance of paper production. Paper machine belts are used in various stages of the papermaking process, including the pressing, drying, and finishing stages. These belts help transport the paper web through the paper machine while maintaining the correct tension and stability.

HEZER’s high-quality paper machine belts are designed to work seamlessly with our forming fabrics and dryer fabrics, ensuring smooth transitions between stages. By reducing friction, improving paper sheet quality, and minimizing maintenance, HEZER’s paper machine belts help papermakers achieve faster production cycles and a more consistent final product.

| Type of Belt | Function | Key Features |

|---|---|---|

| Pressing Belts | Transporting paper through the pressing section | High tensile strength, durability |

| Drying Belts | Transporting paper through the drying section | Heat resistance, low energy consumption |

3. Cutting-Edge Paper Machines: Efficiency at Its Best

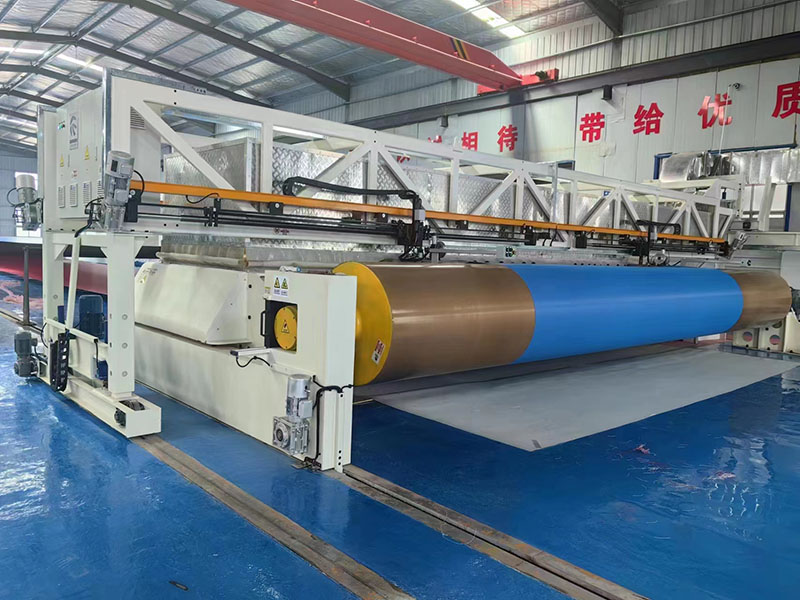

In addition to our papermaking fabrics and paper machine belts, HEZER also provides a range of paper making machines that are designed for maximum efficiency and durability. Our paper machines are equipped with state-of-the-art technology that ensures smooth operation and high output.

Each paper making machine from HEZER is designed with precision engineering to meet the demands of modern papermakers. Whether you are producing fine paper, tissue paper, or packaging paper, HEZER has the right equipment to meet your production needs.

Our machines are optimized to reduce energy consumption, minimize waste, and increase production capacity, making them a valuable investment for papermakers looking to improve both quality and cost-effectiveness.

| Type of Machine | Function | Key Features |

|---|---|---|

| Forming Section | Shaping the paper sheet | High-speed operation, consistent formation |

| Pressing Section | Removing water from the paper web | Reduced energy consumption, enhanced water removal |

| Drying Section | Drying the paper web after pressing | Low energy consumption, high heat resistance |

How HEZER’s End-to-End Solutions Improve Paper Production

HEZER’s end-to-end solutions offer papermakers a complete package that covers all aspects of the papermaking process. Here’s how our products work together to improve paper production efficiency:

-

Optimized Paper Machine Clothing: Our high-quality forming fabrics and dryer fabrics are engineered to reduce downtime and improve the quality of the paper sheet. These fabrics ensure smooth transport of the paper web through the paper machine while minimizing defects and inconsistencies.

-

Seamless Integration with Paper Machine Belts: Our paper machine belts are designed to integrate seamlessly with the other components, ensuring that the paper web is transported efficiently between sections of the machine without causing friction or damage.

-

Advanced Paper Making Machines: Our paper making machines are designed to work with our fabrics and belts to create a streamlined production process. Each machine is equipped with the latest technology, which ensures maximum efficiency and consistent output.

The Benefits of Choosing HEZER’s Paper Manufacturing Solutions

By choosing HEZER’s paper manufacturing solutions, papermakers benefit from:

-

Improved Production Efficiency: HEZER’s products are designed to streamline the papermaking process, reduce energy consumption, and increase production speed.

-

High-Quality Paper Products: Our papermaking fabrics and paper machine belts are engineered to deliver superior paper quality, ensuring that your products meet the highest standards.

-

Reduced Downtime: With our durable and reliable solutions, papermakers experience less downtime and fewer maintenance issues, leading to greater profitability.

-

Tailored Solutions: HEZER provides customized solutions to meet the specific needs of each papermaker, ensuring that our products are optimized for your production requirements.

Why Choose HEZER for Your Paper Manufacturing Needs?

HEZER has been a leader in the papermaking industry for over 22 years. Our expertise, commitment to innovation, and high-quality products have made us a trusted partner for papermakers around the world. By choosing HEZER, you gain access to a comprehensive range of paper manufacturing solutions that will improve the efficiency and quality of your production process.

For more information about our products, please visit HEZER’s website. Explore our offerings and see how we can help optimize your papermaking process today.

Conclusion

Choosing the right paper manufacturing solutions is crucial for improving efficiency, reducing costs, and ensuring high-quality output. With HEZER’s comprehensive range of products, including papermaking fabrics, paper machine belts, and paper making machines, you can streamline your entire production process. Our end-to-end support helps papermakers optimize every stage of production, leading to enhanced productivity and superior paper quality. Explore our solutions today and take your papermaking operations to the next level.