The clothing industry is constantly evolving, driven by technological advancements, new consumer demands, and ever-changing market dynamics. One such advancement that is making waves in the industry is the evolution of the paper making machine used in clothing production. While the primary focus of most clothing manufacturers is on garment production, machinery plays a significant role in creating the essential materials used in fashion. In particular, the paper-making industry, and the paper machine clothing market, are key components in ensuring the high-quality production of clothing fabrics.

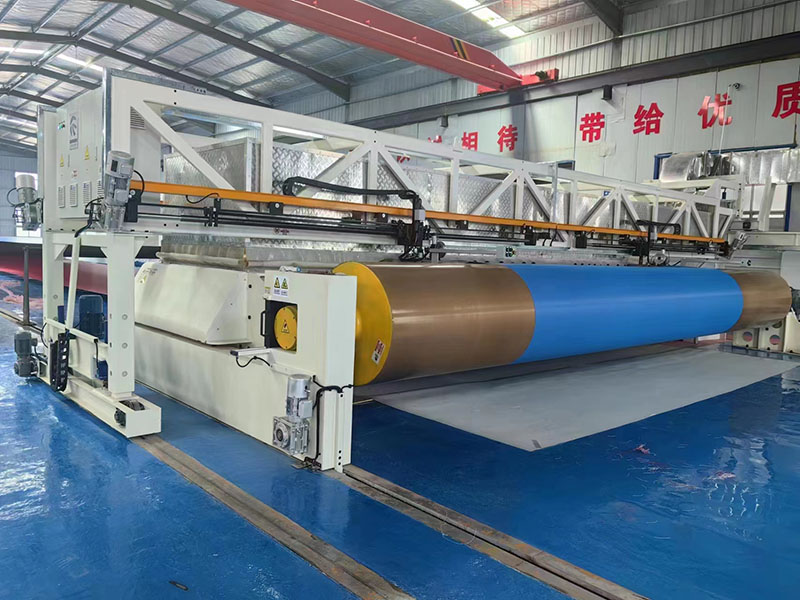

At Hezerbelt, a leading manufacturer based in China, innovations in paper machines and machine clothing have become an integral part of the clothing production process. Let’s dive into how paper-making machinery is transforming the clothing industry in 2025.

Understanding the Role of Paper Making Machines in Clothing Production

Paper making machines are essential in producing the right kind of fabric for clothing. These machines use specialized belts that help in the creation of paper-based materials used in various stages of garment production. With innovation, the technology behind paper machines has evolved, ensuring better efficiency, enhanced durability, and more versatile fabric materials.

In the context of clothing production, these machines are especially important for creating high-quality, efficient materials such as forming fabrics, dryer fabrics, and filter belts. Let’s break down these three essential types of fabric used in the clothing industry:

1. Forming Fabrics

Forming fabrics are used in the initial stages of the paper-making process. These fabrics create the base layer for the paper or fabric by transferring pulp onto a wire mesh. In the clothing industry, forming fabrics are used to create uniform and smooth fabric surfaces. Hezerbelt’s high-quality forming fabrics ensure that the fabric formed during production is perfectly even, which is crucial for garment manufacturing. With the latest innovations in forming fabrics, Hezerbelt ensures that fabric creation is precise, efficient, and cost-effective.

2. Dryer Fabrics

Once the forming fabrics have created the initial structure of the material, dryer fabrics come into play. These fabrics help in drying the material once it has passed through the paper machine. Hezerbelt’s dryer fabrics are designed to handle high temperatures and provide consistent moisture removal during the drying process. This guarantees that the fabric produced is of the highest quality and ready for the next step in the clothing manufacturing process.

3. Filter Belts

Filter belts are used in paper making to remove unwanted substances from the paper pulp, improving the overall quality of the fabric. These belts are especially important in ensuring that the paper or fabric is free of impurities and contaminants. Hezerbelt’s filter belts provide exceptional filtration performance, ensuring the final product meets the strictest quality standards required for clothing production.

How China Leads the Way in Paper Making Machines for Clothing Manufacturers

The China clothing manufacturer industry is a global leader in both garment production and textile machinery innovation. The integration of advanced paper making machines into the clothing manufacturing process is just one example of how Hezerbelt has been at the forefront of this evolution.

Chinese manufacturers like Hezerbelt are known for producing high-quality, durable, and efficient paper making machines. These machines play a pivotal role in streamlining the production of forming fabrics, dryer fabrics, and filter belts that are crucial to the clothing industry. As one of the top manufacturers in China, Hezerbelt provides cutting-edge machinery and fabric solutions to global markets.

One of the standout features of Hezerbelt’s paper machines is their ability to offer customizable options tailored to the specific needs of various industries, including the clothing production sector. This adaptability is a key factor in the success of the company, as it ensures that manufacturers can achieve the highest standards of fabric production.

The Benefits of Working with Hezerbelt: China’s Leading Manufacturer

When choosing a partner for paper machines or clothing manufacturing equipment, it’s essential to select a manufacturer that can provide high-quality products, fast lead times, and cost-effective solutions. Hezerbelt has proven to be a reliable partner for clothing manufacturers worldwide. Here are some benefits of working with Hezerbelt:

-

Innovation in Fabric Technology

Hezerbelt continually invests in research and development, bringing the latest innovations to their customers. Whether you’re looking for advanced forming fabrics, dryer fabrics, or filter belts, Hezerbelt offers innovative solutions that improve the overall efficiency and quality of your production line. -

Quality Assurance

The company ensures that every machine and fabric they produce undergoes rigorous quality control processes. This commitment to quality makes Hezerbelt a trusted name in the clothing manufacturing and paper machine industry. -

Global Reach

As a manufacturer in China, Hezerbelt has a global reach, serving clothing manufacturers across the world. Their wide range of products, including paper machines and machine clothing, has earned them a solid reputation in the textile industry. -

Customer-Centric Approach

Hezerbelt works closely with clients to understand their unique needs and provide tailored solutions. Whether you’re looking for new dryer fabrics or optimizing existing machines, the company’s expertise ensures that your production goals are met with precision and efficiency.

The Future of Paper Machines and Clothing Production

As we look toward 2025, the future of clothing production and the machinery used to create fabrics is full of exciting possibilities. Innovations in paper machines are expected to continue pushing the boundaries of what is possible in textile production.

Some of the trends to look out for in the coming years include:

-

Increased Automation: More clothing manufacturers will turn to automated solutions for both fabric production and garment manufacturing. This will help streamline processes and reduce the time and costs associated with production.

-

Sustainability: With growing concerns about environmental impact, sustainable production practices will become a priority for both paper manufacturers and clothing manufacturers. Expect to see an increase in eco-friendly fabrics and energy-efficient machinery.

-

Smart Fabrics: The integration of technology into fabrics, such as fabrics that monitor body temperature or track health metrics, is likely to grow. Paper-making machinery may be adapted to accommodate the creation of these high-tech fabrics.

-

Customization: As the demand for unique, tailored clothing grows, manufacturers will need to implement machines and fabrics that can offer more customization options in fabric design, color, and texture.

Conclusion

The future of clothing manufacturing and paper making machines is looking incredibly promising as advancements continue to evolve. Companies like Hezerbelt are at the forefront of these changes, providing innovative forming fabrics, dryer fabrics, and filter belts that help manufacturers produce the highest-quality clothing materials.

As a clothing manufacturer or paper manufacturer, working with Hezerbelt means you’re investing in cutting-edge technology, sustainable practices, and high-quality machinery that can take your production process to the next level. Whether you’re looking for reliable machine clothing or efficient paper-making machines, Hezerbelt has the expertise and resources to meet your needs.

To learn more about our paper machine clothing, forming fabrics, and other innovative solutions, visit our website at Hezerbelt.