Introduction: The Importance of Paper Machine Clothing in Paper Production

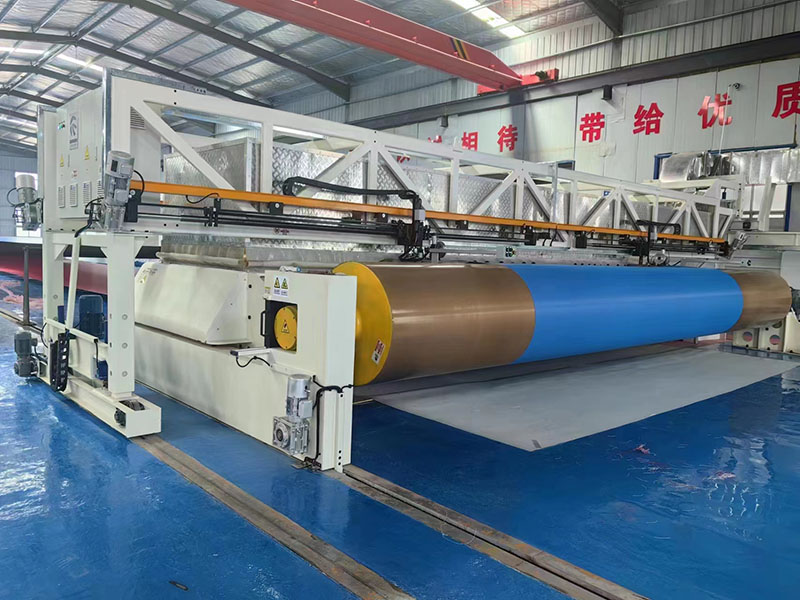

Paper machine clothing (PMC) refers to a range of fabrics designed to be used in the papermaking process. These textiles are essential components of paper machines, which are responsible for producing everything from office paper to industrial paper products. Paper machine clothing manufacturers design these fabrics with extreme precision to ensure they can handle the demanding tasks involved in paper production. By improving the efficiency and quality of paper production, these fabrics play a pivotal role in the industry.

In this blog, we will delve into what paper machine clothing is, its critical role in paper production, and why choosing the right PMC manufacturer is key to ensuring optimal performance. We will also explore frequently asked questions (FAQs) about paper machines and their operations, highlighting how HEZER Belt contributes to advancing the technology and performance of paper machine clothing.

What is Paper Machine Clothing?

Paper machine clothing is a set of specialized fabrics used at various stages of the papermaking process. The paper machine itself consists of several sections where these fabrics are utilized to shape, press, and dry the paper. The primary function of paper machine clothing is to provide a stable surface for the paper to form, remove water during the production process, and ensure the paper dries uniformly.

There are different types of PMC, each designed to meet specific requirements in the paper production process:

-

Forming Fabrics: These are used in the forming section of the paper machine where the paper sheet is initially formed and excess water is removed.

-

Press Fabrics: These fabrics help press the paper as it moves through the press section, where more water is squeezed out to ensure uniformity and reduce weight.

-

Dryer Fabrics: Located in the drying section, these fabrics ensure that the paper is completely dried as it passes through heated rollers.

By using advanced paper machine clothing, manufacturers can improve the overall performance of the paper machine, enhancing paper quality and production efficiency.

The Role of Paper Machine Clothing Manufacturers

Paper machine clothing manufacturers play a crucial role in ensuring the success of paper mills worldwide. They design and produce fabrics that meet the specific needs of paper machines, tailored to different machine speeds, paper types, and environmental conditions. Some key responsibilities of these manufacturers include:

-

Customization: Each paper mill operates under unique conditions. Manufacturers like HEZER Belt provide custom paper machine clothing solutions that are specifically designed to optimize each mill’s production process.

-

Durability and Quality: Paper machines operate in harsh environments, and PMC must be durable enough to withstand constant wear and tear. Manufacturers use high-quality materials and advanced construction techniques to ensure longevity and optimal performance.

-

Efficiency: Efficient paper machine clothing reduces machine downtime, increases production output, and minimizes energy consumption. This is especially important in high-speed machines that demand consistent performance from the fabrics.

At HEZER Belt, they specialize in delivering high-performance PMC, ensuring that every piece of clothing they produce helps paper mills achieve their production goals. They have over 20 years of experience in providing customized solutions for paper mills worldwide. Their dedication to quality, customer satisfaction, and innovation has made them a leader in the paper machine clothing industry.

The Paper Manufacturing Process and the Role of Paper Machine Clothing

The paper manufacturing process is a complex series of steps that requires precision and care. Paper machine clothing is crucial in ensuring that each phase of the process is carried out efficiently and without interruption. Here’s a quick overview of how PMC is used at various stages of the paper production line:

-

Forming Section: Paper pulp is spread across the forming fabric, and water is drained to create a continuous sheet of paper. Forming fabrics provide the surface on which the paper sheet is formed.

-

Pressing Section: The sheet is passed through a series of rollers covered with press fabrics, which help to remove additional water and smooth the paper.

-

Drying Section: The paper moves through dryer fabrics to remove the remaining moisture as the paper is dried by heated rollers.

At each stage, the quality and performance of paper machine clothing are critical to achieving high-quality paper and maximizing production efficiency.

FAQs About Paper Machines and Paper Machine Clothing

To better understand the importance of paper machine clothing, let’s address some frequently asked questions (FAQs) that are commonly asked by those involved in the paper industry.

1. What is paper machine clothing used for?

Paper machine clothing is used in paper machines to facilitate the production of paper by supporting the paper sheet as it forms, presses, and dries. PMC includes fabrics for each section of the paper machine—forming, pressing, and drying—each designed to optimize water removal, reduce friction, and enhance the overall paper quality.

2. What does the paper machine do?

A paper machine is a mechanical device used to produce paper. It uses pulp and converts it into a continuous sheet of paper through a series of mechanical, chemical, and thermal processes. The paper machine is divided into several sections, including forming, pressing, and drying, where paper machine clothing is essential for the operation.

3. What does a paper machine operator do?

A paper machine operator monitors and controls the operation of the paper machine. They ensure that the machine runs smoothly, troubleshoot issues, and maintain the machinery to ensure that the paper production process is as efficient and cost-effective as possible.

4. What is a breast roll in a paper machine?

The breast roll is a crucial part of the paper machine that helps in the formation of the paper sheet. Located in the forming section, it supports the wire and helps in dewatering the pulp, ensuring that the paper sheet is uniform and consistent.

5. What is the history of the paper machine?

The first mechanical paper machine was invented in the early 19th century, revolutionizing paper production by automating the process. Over the years, advancements in technology have led to faster, more efficient machines, and paper machine clothing has evolved to meet the demands of these innovations.

6. What are the two types of paper machines?

There are two primary types of paper machines: Fourdrinier machines and Twin-wire machines. The Fourdrinier machine is the most common, using a single wire to form the paper sheet, while the Twin-wire machine uses two wires to form the paper, allowing for higher-quality paper and faster production speeds.

Why Choose HEZER Belt for Paper Machine Clothing?

HEZER Belt is a global leader in the production of paper machine clothing, offering customized solutions that meet the specific needs of paper mills. With over 20 years of experience, the company specializes in delivering high-performance PMC that improves the efficiency, longevity, and quality of paper machines.

Here are a few reasons why HEZER Belt is a trusted partner for paper mills around the world:

-

Expertise: With over two decades of experience, HEZER Belt is known for its deep understanding of the paper production process.

-

Customization: They provide tailor-made solutions for every paper mill, ensuring optimal performance and efficiency.

-

Quality Assurance: HEZER Belt manufactures high-quality paper machine clothing using the finest materials and state-of-the-art manufacturing techniques.

-

Sustainability: They are committed to providing eco-friendly PMC options that reduce environmental impact and improve energy efficiency.

Learn more about HEZER Belt and their high-quality paper machine clothing solutions by visiting their official website at HEZER Belt and read about their story and values in more detail at About Us.

Conclusion: The Future of Paper Machine Clothing

As the paper industry continues to evolve, the demand for more efficient and sustainable solutions in paper machine clothing will only grow. Paper machine clothing manufacturers like HEZER Belt are at the forefront of this innovation, providing custom PMC that optimizes paper production, improves energy efficiency, and reduces environmental impact.

To explore HEZER Belt’s range of paper machine clothing solutions and learn how they can improve your paper production process, visit HEZER Belt and About Us.