Introduction

Paper production is a highly intricate process that involves numerous components working together to create the final product. One of the most critical elements in this process is paper machine clothing (PMC), which plays a crucial role in determining the efficiency, durability, and quality of the paper produced. In this blog, we will delve into why quality paper machine clothing matters, how it impacts the paper manufacturing process, and why investing in top-tier materials can make a significant difference in your production outcomes.

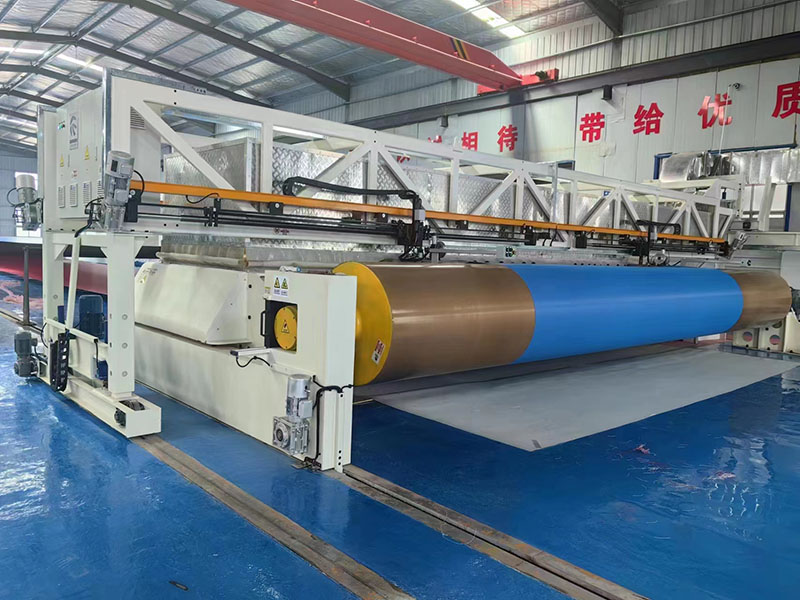

What is Paper Machine Clothing?

Paper machine clothing refers to the fabric used in paper machines to support and assist in various stages of the papermaking process. These include dewatering, pressing, and drying phases, where the paper web is formed, pressed, and dried to achieve the desired characteristics. The clothing is typically made from synthetic or natural fibers, woven into different textures and designs to meet specific needs within the paper production process.

Common types of paper machine clothing include:

-

Forming Fabrics: These are used during the initial stage when the paper web is formed.

-

Press Felts: These are used during the pressing phase to remove excess water from the web.

-

Dryer Fabrics: These are used in the drying section to ensure uniform drying and smoothness of the paper.

Why Quality Paper Machine Clothing Matters

1. Enhances Production Efficiency

The primary function of PMC is to ensure that the papermaking process runs smoothly and efficiently. High-quality paper machine clothing enhances production efficiency in the following ways:

-

Improved Dewatering: Quality PMC ensures efficient water removal during the forming and pressing stages, which is crucial for reducing drying times. The quicker the water is removed, the more energy-efficient the drying process becomes, resulting in lower production costs.

-

Reduced Downtime: Poor quality or worn-out PMC can cause frequent machine breakdowns and disruptions, leading to costly downtime. Quality materials help reduce these occurrences by ensuring better durability and a longer lifespan.

-

Faster Pressing: In the pressing stage, good PMC ensures that water is removed efficiently, leading to a faster and more consistent process, which speeds up the overall production cycle.

2. Improves Paper Quality

The type and quality of PMC used in the production process directly influence the quality of the final paper product. Here are a few ways in which quality PMC can improve paper quality:

-

Consistency in Texture: Well-designed and properly woven PMC fabrics ensure that the paper’s texture is uniform. This leads to smooth and consistent paper, free from defects such as wrinkles or uneven texture.

-

Better Surface Finish: A high-quality dryer fabric contributes to a smoother finish and better printability of the paper. This is particularly crucial for industries that require high-quality printing, such as the packaging and publishing sectors.

-

Reduced Defects: High-quality fabrics in the forming, pressing, and drying stages help minimize the risk of defects in the paper, such as holes, tears, or blotches.

3. Longer Lifespan and Reduced Costs

One of the most significant advantages of investing in quality paper machine clothing is its longevity. Premium PMC fabrics are designed to last longer, even under high-pressure and high-temperature conditions. Here are some benefits:

-

Durability: Quality fabrics are made from superior materials that can withstand the harsh conditions in the papermaking process. This reduces the need for frequent replacements, saving on material costs.

-

Lower Maintenance Costs: Durable PMC reduces the wear and tear on your paper machine, meaning less maintenance is required. This helps reduce repair costs and ensures that your equipment operates at peak efficiency.

4. Environmental Benefits

Sustainability is becoming an increasingly important consideration in the paper industry. Investing in high-quality paper machine clothing can also help reduce the environmental impact of paper production:

-

Reduced Energy Consumption: As previously mentioned, efficient dewatering and faster drying times lead to lower energy consumption. Using quality PMC helps reduce the carbon footprint of your production process.

-

Waste Reduction: Better paper quality means fewer defects, which in turn reduces waste. By improving the overall efficiency of the paper machine, quality PMC helps minimize paper waste during production.

Key Factors to Consider When Choosing Paper Machine Clothing

When selecting paper machine clothing, there are several factors to consider to ensure that you are investing in the right materials for your specific needs:

1. Material Composition

The material composition of PMC fabrics affects their strength, durability, and performance. Materials like polyester and nylon are commonly used because they offer excellent wear resistance, but the choice of material should depend on your specific machine and production process.

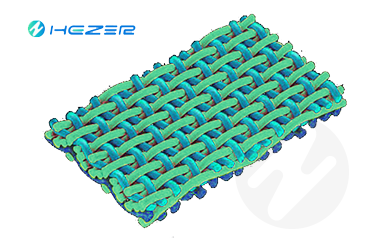

2. Fabric Design

The design and construction of the fabric are crucial for its performance. Factors like the weave pattern, pore size, and thickness determine how well the PMC will perform in each phase of the papermaking process. Make sure to choose fabrics that meet the needs of your machine and paper type.

3. Machine Compatibility

Paper machines vary in design and configuration, which means that the PMC must be compatible with the machine’s specific requirements. Ensure that the clothing is designed for the specific conditions of your machine, including temperature, pressure, and speed.

4. Cost-Effectiveness

While it’s tempting to choose lower-cost PMC fabrics, it’s essential to balance cost with performance. Poor-quality fabrics may save you money in the short term but could lead to higher costs due to frequent replacements, downtime, and production inefficiencies.

How to Optimize Your Paper Production with Quality Paper Machine Clothing

Regular Maintenance and Replacement

Even the best quality paper machine clothing will eventually wear out. Regular maintenance and timely replacement are crucial to maintaining optimal production performance. Create a schedule for inspecting and replacing your PMC to ensure that your paper machine runs smoothly at all times.

Monitor Production Conditions

Keep track of key production parameters such as temperature, pressure, and speed to ensure that they are within the optimal range for your paper machine clothing. Monitoring these conditions will help you identify when your PMC needs replacement and prevent unnecessary wear.

Work with Trusted Suppliers

To ensure the quality of your paper machine clothing, work with reputable suppliers who specialize in high-quality fabrics. Look for suppliers that provide detailed specifications and offer support to help you select the right clothing for your specific needs.

Conclusion

In conclusion, the importance of quality paper machine clothing cannot be overstated. By investing in high-quality PMC, you can improve the efficiency, durability, and quality of your paper production process. Not only will this lead to lower costs and better products, but it will also help reduce your environmental impact. By carefully selecting the right paper machine clothing for your operation and ensuring regular maintenance, you can optimize your paper manufacturing process and achieve long-term success.

For more information on quality paper machine clothing, visit Hezerbelt.

Internal Links

-

Why Quality Paper Machine Clothing is Vital for the Paper Industry

-

Sustainability in Paper Production: How to Minimize Environmental Impact

-

Optimizing Paper Production Equipment for Maximum Performance

Table: Common Types of Paper Machine Clothing

| Type of Paper Machine Clothing | Function | Material Composition | Recommended Use |

|---|---|---|---|

| Forming Fabrics | Paper web formation | Polyester, Nylon | Paper sheet formation |

| Press Felts | Water removal | Polyester, Aramid | Pressing phase |

| Dryer Fabrics | Drying and finishing | Polyester, Silk | Drying phase |

By understanding the role of paper machine clothing in the papermaking process and investing in quality materials, paper producers can ensure that their operations are more efficient, sustainable, and cost-effective in the long run.