Introduction: The Cutting Edge of Paper Production Technology

At HezeRbelt, we’re at the forefront of revolutionizing paper machine clothing through continuous innovation. Today’s paper machine clothing is undergoing a technological transformation that’s reshaping production efficiency, paper quality, and operational sustainability. Gone are the days of simple woven fabrics – modern designs incorporate advanced materials, smart technologies, and precision engineering that push the boundaries of paper manufacturing.

This comprehensive guide explores the groundbreaking innovations transforming paper machine clothing. We’ll examine material science breakthroughs, structural engineering advancements, smart technology integration, and sustainability-focused designs that are setting new standards in the industry.

Material Science Breakthroughs

Modern materials are redefining clothing performance:

Advanced Material Comparison

| Material | Key Properties | Applications | Benefits |

|---|---|---|---|

| High-Performance Polyester | Enhanced strength, heat resistance | Forming, pressing | Longer lifespan, higher speeds |

| PPS (Polyphenylene Sulfide) | Exceptional chemical resistance | Challenging chemical environments | Reduced degradation |

| Hybrid Polymer Blends | Custom property combinations | Specialty grades | Tailored performance |

| Nanocomposite Coatings | Ultra-smooth, anti-adhesive surfaces | Premium grades | Superior sheet release |

| Bio-Based Polymers | Renewable sources | Eco-conscious production | Reduced carbon footprint |

Discover our innovative material solutions.

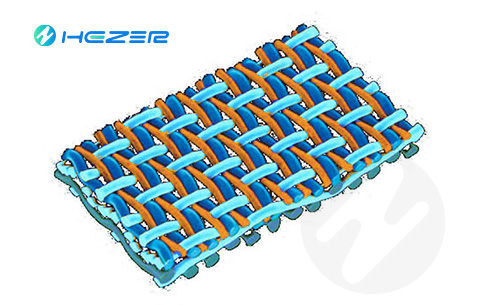

Structural Engineering Innovations

Revolutionary designs optimize every aspect of performance:

Structural Advancements by Clothing Type

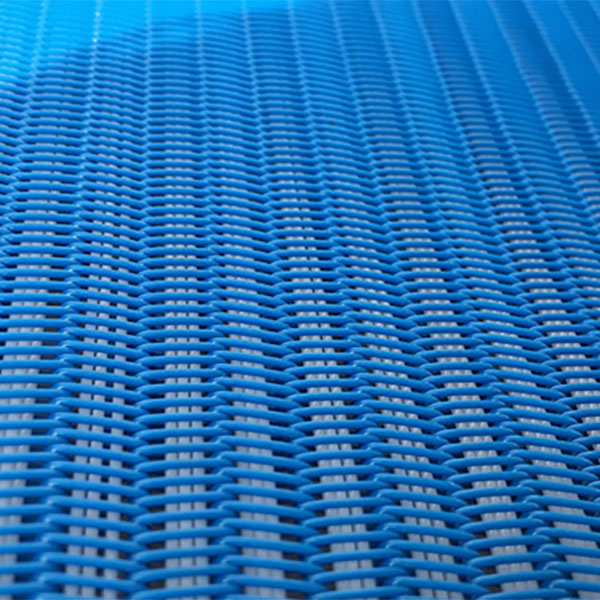

Forming Fabrics:

- Multi-layer 3D weaves for improved drainage

- Zone-specific designs for uniform formation

- Asymmetric structures for reduced two-sidedness

Press Felts:

- Gradient density constructions

- Composite batt systems

- Reinforced edge technologies

Dryer Fabrics:

- Open matrix designs for enhanced airflow

- Low-contact surface patterns

- Integrated stability layers

Explore our structural innovations in detail.

Smart Technology Integration

The rise of intelligent paper machine clothing:

Smart Clothing Features

| Technology | Function | Benefit |

|---|---|---|

| Embedded Sensors | Real-time tension monitoring | Predictive maintenance |

| RFID Tags | Lifecycle tracking | Optimal replacement timing |

| Conductive Threads | Wear detection | Prevent unexpected failures |

| Temperature Sensors | Heat profile monitoring | Energy optimization |

| Moisture Detection | Water content analysis | Quality control |

Learn about our smart clothing solutions.

Sustainability-Driven Innovations

Eco-conscious designs reducing environmental impact:

Sustainable Innovation Highlights

- Energy-Efficient Designs

- Reduced drying energy requirements

- Lower drive power consumption

- Heat recovery optimization

- Extended Lifespan Technologies

- Wear-resistant surfaces

- Enhanced structural integrity

- Self-repairing coatings

- Circular Economy Solutions

- Recyclable material compositions

- Take-back programs

- Refurbishment services

Our sustainability initiatives deliver measurable environmental benefits.

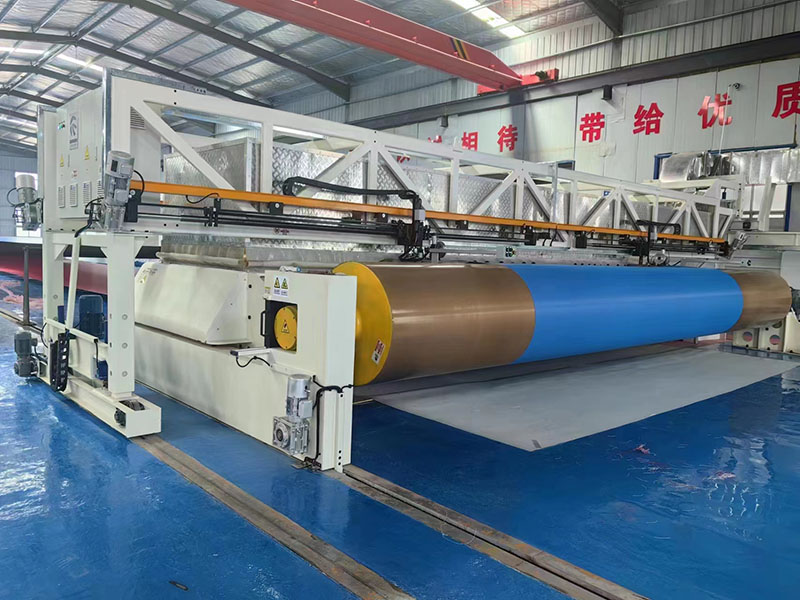

Precision Manufacturing Technologies

Advanced production methods enabling new possibilities:

Cutting-Edge Manufacturing Techniques

| Technology | Application | Advantage |

|---|---|---|

| Computer-Controlled Weaving | Precise pattern execution | Consistent quality |

| Laser Measurement Systems | Micron-level accuracy | Perfect dimensional control |

| Automated Inspection | 100% quality verification | Zero defect guarantee |

| 3D Printing | Custom components | Rapid prototyping |

| AI-Assisted Design | Performance optimization | Ideal property balancing |

See our precision manufacturing in action.

Digital Twin Technology

Virtual simulation transforming clothing development:

Digital Twin Applications

- Performance Prediction

- Simulate drainage characteristics

- Model wear patterns

- Forecast lifespan

- Troubleshooting

- Diagnose quality issues

- Identify root causes

- Test solutions virtually

- Optimization

- Grade change planning

- Speed increase analysis

- Energy saving simulations

Explore our digital twin capabilities.

Customization and Personalization

Tailored solutions for unique production needs:

Custom Innovation Options

| Customization Area | Possibilities | Benefit |

|---|---|---|

| Weave Patterns | Grade-specific designs | Optimized performance |

| Material Blends | Property customization | Perfect application match |

| Surface Treatments | Special coatings | Enhanced functionality |

| Edge Technologies | Reinforcement options | Extended service life |

| Composite Structures | Multi-layer solutions | Combined benefits |

Our custom design service creates perfect-fit innovations.

Industry 4.0 Integration

Connected clothing in smart paper mills:

Connected Clothing Features

- Cloud-Based Monitoring

- Remote performance tracking

- Historical data analysis

- Predictive analytics

- Automated Adjustment

- Self-optimizing tension

- Adaptive cleaning systems

- Real-time parameter changes

- System Integration

- Mill-wide optimization

- Grade change automation

- Energy management

Discover our Industry 4.0 solutions.

Future Trends and Emerging Technologies

What’s next in paper machine clothing innovation:

Coming Innovations

- Self-Cleaning Surfaces

- Nano-structured textures

- Hydrophobic coatings

- Photocatalytic materials

- Self-Healing Materials

- Microcapsule repair systems

- Shape memory polymers

- Autonomous damage response

- Biomimetic Designs

- Nature-inspired structures

- Adaptive permeability

- Dynamic surface properties

Stay ahead with our innovation forecasts.

Case Studies: Innovation in Action

Real-world examples of transformative results:

Innovation Impact Examples

| Mill Challenge | Innovative Solution | Results Achieved |

|---|---|---|

| High energy costs | Low-friction dryer fabric | 22% energy reduction |

| Frequent clothing changes | Extended-life forming fabric | 40% longer lifespan |

| Quality inconsistencies | Smart press felt with sensors | 15% defect reduction |

| Chemical degradation | PPS-based clothing system | 3x chemical resistance |

| Slow grade changes | Adaptive design clothing | 50% faster transitions |

Read more success stories.

Implementing Innovations in Your Mill

Practical steps to adopt new technologies:

Innovation Adoption Roadmap

- Assessment

- Identify pain points

- Evaluate current performance

- Set improvement goals

- Selection

- Research solutions

- Consult experts

- Pilot testing

- Implementation

- Phased installation

- Staff training

- Performance monitoring

- Optimization

- Fine-tuning

- Process adjustment

- Continuous improvement

Our innovation adoption program guides you through each step.

Conclusion: Embracing the Future of Paper Machine Clothing

The paper machine clothing industry is experiencing an unprecedented wave of innovation that’s transforming paper manufacturing. From advanced materials that last longer to smart technologies that predict maintenance needs, these developments are helping paper producers achieve new levels of efficiency, quality, and sustainability.

At HezeRbelt, we’re proud to be driving this innovation forward through continuous research, development, and collaboration with our customers. Our commitment to innovation ensures that paper manufacturers have access to the most advanced clothing solutions available anywhere in the world.

Ready to explore how these innovations can benefit your operation? Contact our innovation team today or browse our latest innovative products. Let’s work together to bring the future of paper machine clothing to your mill today.