Introduction: The Sustainability Imperative in Paper Manufacturing

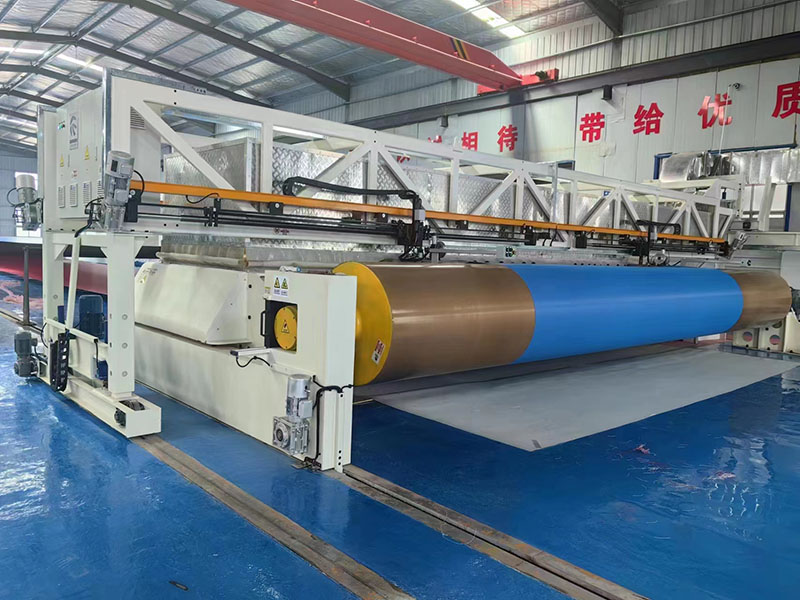

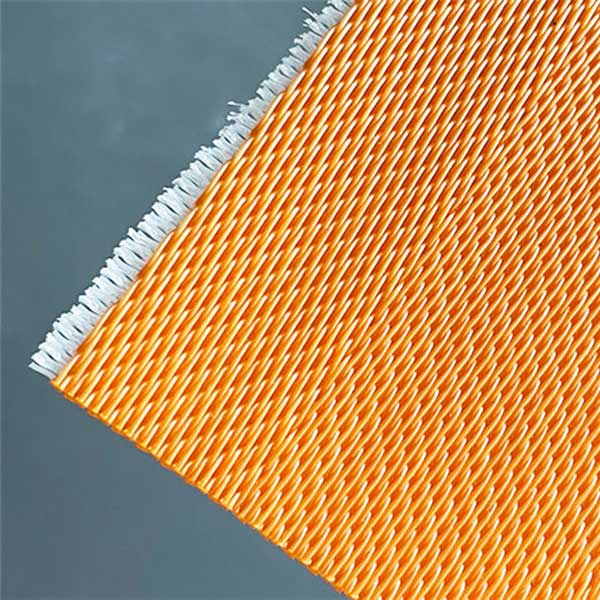

At HezeRbelt, we recognize that sustainability has become a critical priority for paper manufacturers worldwide. While much attention focuses on fiber sourcing and chemical processes, paper machine clothing plays an equally vital role in creating environmentally responsible paper production. These essential components – forming fabrics, press felts, and dryer screens – significantly influence energy consumption, water usage, material efficiency, and overall environmental footprint.

This comprehensive guide explores how strategic selection and maintenance of paper machine clothing can contribute to more sustainable paper production. We’ll examine the environmental impacts throughout the clothing lifecycle, innovative eco-friendly solutions, and best practices for maximizing sustainability without compromising performance.

The Environmental Impact of Paper Machine Clothing

Understanding the full sustainability picture requires examining all phases of machine clothing’s lifecycle:

Lifecycle Environmental Impacts

| Lifecycle Stage | Key Sustainability Factors | Potential Improvements |

|---|---|---|

| Raw Material Production | Energy use, chemical processing, material sourcing | Recycled materials, bio-based polymers |

| Manufacturing | Water consumption, energy use, waste generation | Efficient production methods, renewable energy |

| Transportation | Fuel consumption, emissions | Local sourcing, optimized logistics |

| In-Use Performance | Energy efficiency, water conservation, chemical use | High-performance designs, extended lifespan |

| End-of-Life | Recyclability, disposal methods | Take-back programs, material recovery |

Our sustainability assessment tools help quantify these impacts for your specific operation.

Energy Efficiency: The Hidden Sustainability Lever

Paper machine clothing significantly influences energy consumption, particularly in drying:

Energy Savings Opportunities

- Enhanced Drainage Fabrics

- Reduce water content entering dryers

- Can lower steam consumption by 15-25%

- Our high-drainage fabrics demonstrate proven results

- Advanced Press Felts

- Higher compression resistance maintains efficiency

- Improved water removal reduces drying load

- Specialized designs for different paper grades

- Optimized Dryer Fabrics

- Increased air permeability improves heat transfer

- Reduced contact area lowers energy demand

- Advanced materials withstand higher temperatures

Case Study: A European mill achieved 18% energy reduction in drying after switching to our energy-optimized clothing system.

Water Conservation Through Smart Clothing Choices

Water usage represents another critical sustainability factor influenced by machine clothing:

Water Reduction Strategies

- Improved Forming Fabrics

- Faster initial drainage reduces freshwater needs

- Cleaner surfaces require less shower water

- Specialized designs for closed water systems

- Efficient Cleaning Systems

- Targeted shower systems minimize water use

- Automated controls adjust to production conditions

- Our water-smart solutions integrate these features

- Contamination Resistance

- Reduced plugging means less cleaning water

- Special coatings prevent buildup

- Open designs improve cleaning efficiency

Extended Lifespan: Reducing Waste Through Durability

Longer-lasting machine clothing directly reduces environmental impact:

Lifespan Extension Approaches

| Strategy | Implementation | Sustainability Benefit |

|---|---|---|

| Advanced Materials | High-tenacity polymers, wear-resistant coatings | 30-50% longer service life |

| Proper Maintenance | Regular cleaning, tension monitoring | Maximizes usable lifespan |

| Repair Programs | Professional patching, edge repair | Avoids premature replacement |

| Optimal Selection | Grade-specific designs | Matches performance to needs |

Our fabric longevity program combines these approaches for maximum sustainability.

Sustainable Material Innovations

New material developments are transforming machine clothing sustainability:

Eco-Friendly Material Options

- Recycled Content Fabrics

- Contain post-industrial recycled polymers

- Maintain performance while reducing virgin material use

- Available in select product lines

- Bio-Based Polymers

- Renewable raw material sources

- Reduced carbon footprint

- Currently in development stages

- Low-Impact Coatings

- Water-based instead of solvent-based

- Reduced VOC emissions

- Equal or better performance characteristics

Explore our eco-material options for your specific needs.

Chemical Reduction Through Smart Design

Machine clothing choices can minimize chemical usage:

Chemical Use Reduction Strategies

- Anti-Contamination Fabrics

- Resist buildup naturally

- Require less frequent chemical cleaning

- Special surface treatments

- Easy-Clean Designs

- Open structures facilitate cleaning

- Smooth surfaces prevent adhesion

- Reduce cleaning chemical quantities

- Process Optimization

- Proper clothing selection reduces need for additives

- Balanced systems minimize chemical corrections

- Our chemical reduction program provides guidance

Circular Economy Solutions

Closing the loop on machine clothing lifecycle:

Circular Economy Initiatives

- Take-Back Programs

- Responsible end-of-life processing

- Material recovery options

- Certified recycling partners

- Refurbishment Services

- Professional cleaning and inspection

- Performance restoration

- Cost-effective alternative to new purchases

- Component Recycling

- Polymer recovery for reuse

- Metal part recycling

- Waste minimization

Learn about our circular economy commitments.

Measuring and Reporting Sustainability Impact

Quantifying improvements is essential for continuous progress:

Key Performance Indicators

| KPI | Measurement Method | Improvement Targets |

|---|---|---|

| Energy Consumption | kWh/ton of paper | 5-15% reduction |

| Water Usage | m³/ton of paper | 10-20% reduction |

| Clothing Lifespan | Days/months in service | 20-30% increase |

| Waste Generation | kg of waste/ton of paper | 15-25% reduction |

Our sustainability tracking tools help monitor these metrics.

Best Practices for Sustainable Operation

Implementing these operational approaches enhances sustainability:

Sustainable Operation Checklist

- Proper Clothing Selection

- Match specifications to paper grade

- Consider total lifecycle costs

- Consult sustainability experts

- Optimal Maintenance

- Regular cleaning schedules

- Proper tension management

- Timely repairs

- Employee Training

- Sustainable operation practices

- Proper handling techniques

- Early problem identification

- Performance Monitoring

- Track key sustainability metrics

- Regular reviews

- Continuous improvement

Download our complete sustainability best practices guide.

Future Trends in Sustainable Machine Clothing

Emerging technologies promise even greater sustainability:

Coming Innovations

- Smart Clothing with Sensors

- Real-time performance monitoring

- Predictive maintenance

- Automated optimization

- Advanced Material Science

- Self-cleaning surfaces

- Even more durable polymers

- Bio-degradable options

- Digital Twin Technology

- Virtual performance modeling

- Simulation for optimization

- Reduced trial-and-error waste

Stay updated on these developments through our innovation center.

Conclusion: Clothing’s Critical Role in Green Paper Production

Paper machine clothing represents a significant opportunity for paper manufacturers to enhance their sustainability performance. From energy and water savings to extended service life and circular solutions, every aspect of machine clothing selection and maintenance contributes to environmental responsibility.

At HezeRbelt, we’re committed to advancing sustainable paper production through innovative machine clothing solutions. By partnering with us, you gain access to cutting-edge technologies, expert guidance, and measurable sustainability improvements for your operation.

Take the next step toward greener paper production by contacting our sustainability specialists or exploring our range of eco-optimized products. Together, we can make paper manufacturing more sustainable without compromising on quality or productivity.