Introduction to Paper Machine Clothing Manufacturers

Paper mills around the world rely on the precision and durability of paper machine clothing (PMC) to optimize their production processes. Whether it’s for forming, pressing, or drying paper, these fabrics play a pivotal role in determining the final product’s quality, the efficiency of the paper machine, and even the energy consumption in the production line. As paper machine clothing manufacturers continue to innovate, they push the boundaries of technology to meet the diverse needs of paper mills across various sectors.

In this blog, we will explore the significance of paper machine clothing, the role of paper machine clothing manufacturers, and why HEZER Belt stands out as an industry leader with over two decades of experience. We will discuss the importance of customized solutions, the technological advancements driving the industry forward, and how HEZER Belt continues to be a trusted partner for paper mills globally.

What is Paper Machine Clothing and Why is it Important?

Paper machine clothing refers to a range of specially designed fabrics that are used in paper manufacturing machines. These fabrics are essential in several stages of the papermaking process, from forming the paper sheet to pressing and drying it. The performance and quality of the PMC directly affect the paper’s properties, including its thickness, texture, and strength.

There are three primary types of paper machine clothing:

-

Forming Fabrics – These fabrics are used in the initial phase of paper formation. They help shape the paper and remove excess water during the forming process.

-

Press Fabrics – These fabrics are used in the pressing section of the paper machine to extract more water and ensure uniform moisture content in the paper.

-

Dryer Fabrics – In the final phase, dryer fabrics help remove the remaining moisture from the paper sheet as it moves through the drying section of the machine.

The quality and customization of these fabrics are crucial to the efficiency of the entire papermaking process. Poor-quality PMC can lead to machine downtime, lower product quality, and higher energy consumption, making it essential for paper mills to invest in durable and high-performance paper machine clothing.

The Role of Paper Machine Clothing Manufacturers

Paper machine clothing manufacturers play a critical role in ensuring that paper mills receive high-quality fabrics tailored to their specific needs. The design, materials, and construction of these fabrics directly impact the paper machine’s efficiency and the quality of the final product.

There are several factors that PMC manufacturers must consider when developing custom solutions for paper mills:

-

Machine Type and Speed: Different paper machines have varying speeds, which can affect the choice of fabrics. High-speed machines require fabrics that can withstand intense pressure and wear while maintaining their performance.

-

Paper Type: The type of paper being produced influences the choice of fabrics. For instance, forming fabrics for tissue paper may differ from those used in packaging paper production.

-

Environmental Conditions: Paper mills may operate in different environments, with varying temperatures, humidity levels, and chemical exposures, all of which affect the performance of PMC.

-

Customization Needs: Paper mills often require specific fabric designs that optimize moisture removal, wear resistance, and energy efficiency. Customization is key to maximizing production efficiency and product quality.

HEZER Belt is one such manufacturer that excels in creating tailored solutions for paper mills around the world. With over 22 years of expertise, HEZER Belt’s team of engineers and designers work closely with clients to develop custom paper machine clothing that enhances operational performance and extends the lifespan of their paper machines.

Why Choose HEZER Belt as Your Paper Machine Clothing Manufacturer?

HEZER Belt has been a trusted name in the paper machine clothing industry for more than two decades. The company’s commitment to providing high-quality, customized solutions has earned them a strong reputation as one of the leading paper machine clothing manufacturers in the world. Below are some key reasons why paper mills trust HEZER Belt for their PMC needs:

1. Extensive Expertise and Experience

With over 22 years of experience in the industry, HEZER Belt brings invaluable knowledge and technical know-how to the table. Their long-standing presence in the market has allowed them to develop a deep understanding of the unique challenges faced by paper mills and the specific requirements for custom paper machine clothing.

2. Customization for Every Paper Mill

HEZER Belt understands that no two paper mills are the same, which is why they offer custom paper machine clothing solutions tailored to each mill’s specific needs. Whether it’s for high-speed paper production, specialty paper types, or specific environmental conditions, HEZER Belt ensures that their PMC is optimized for each application.

3. High-Quality Materials and Manufacturing

HEZER Belt uses only the finest materials and cutting-edge manufacturing processes to produce their paper machine clothing. Each fabric is rigorously tested for durability, performance, and wear resistance, ensuring that it can withstand the demanding conditions of paper production.

4. Technological Innovation

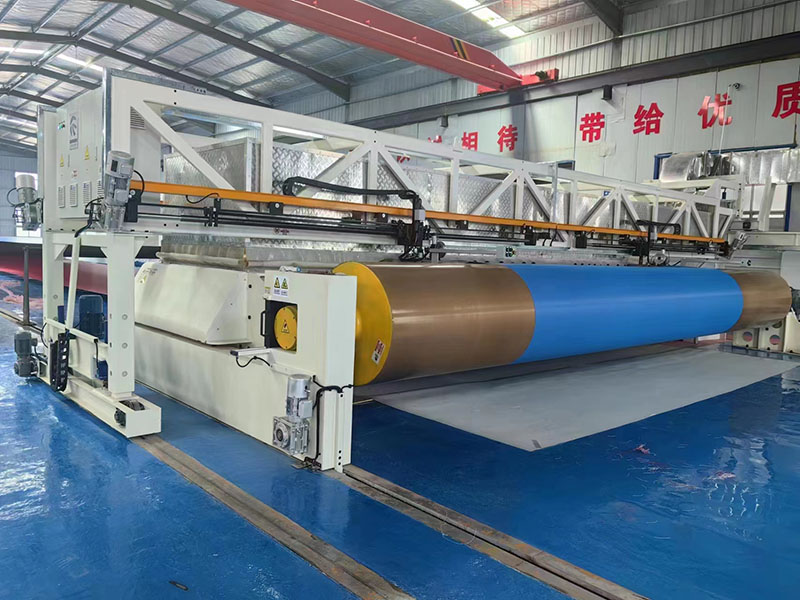

As part of their commitment to continuous improvement, HEZER Belt invests heavily in research and development (R&D). They are constantly exploring new technologies and materials to enhance the performance of their PMC. With state-of-the-art manufacturing facilities, HEZER Belt ensures that their products meet the highest standards of quality and reliability.

5. Global Reach and Support

HEZER Belt has a strong global presence, with a network of distributors and partners serving paper mills across multiple continents. Their international reach ensures that clients have access to timely support and high-quality products wherever they operate.

Technological Advancements in Paper Machine Clothing Manufacturing

As one of the leading paper machine clothing manufacturers, HEZER Belt is at the forefront of technological innovation in the PMC industry. The company’s investment in advanced manufacturing technologies has allowed them to create fabrics that deliver superior performance, durability, and energy efficiency. Some of the key technological advancements in PMC include:

a) Advanced Fiber Technologies

HEZER Belt utilizes advanced fibers and composite materials to create PMC that offer superior strength, wear resistance, and moisture management. These advanced fibers help extend the lifespan of the fabrics, reduce downtime, and improve overall machine efficiency.

b) Enhanced Fabric Designs

Through continuous research and development, HEZER Belt has refined the design of their forming fabrics, press fabrics, and dryer fabrics. Their customized solutions ensure that paper mills can optimize the moisture removal process and improve paper quality.

c) Wear and Tear Resistance

One of the key challenges in the paper industry is wear and tear on paper machine clothing. HEZER Belt’s advanced design techniques ensure that their PMC can withstand harsh operating conditions, reduce maintenance costs, and minimize downtime.

The Future of Paper Machine Clothing: Trends and Innovations

The paper industry is evolving, and so is the demand for more efficient and sustainable solutions in paper production. Paper machine clothing manufacturers are increasingly focusing on the following trends and innovations:

a) Sustainability

Sustainability is becoming a top priority in the paper industry. Manufacturers are developing paper machine clothing made from environmentally friendly materials that reduce waste and energy consumption.

b) Automation and Digitalization

With the increasing adoption of automation and digital technologies in paper mills, paper machine clothing manufacturers are exploring ways to integrate smart technologies into PMC. This includes using sensors to monitor fabric wear and optimize maintenance schedules.

c) Customization through Data

Data-driven insights are helping PMC manufacturers create more precise and customized fabric solutions for paper mills. By leveraging machine learning and data analytics, manufacturers like HEZER Belt can offer tailored fabrics that enhance production efficiency and reduce energy costs.

Conclusion

As the demand for high-quality paper increases, the role of paper machine clothing manufacturers like HEZER Belt becomes even more critical. With over two decades of experience, HEZER Belt continues to set the standard in the industry by providing custom paper machine clothing solutions that enhance efficiency, reduce energy consumption, and improve paper quality. Their focus on innovation, sustainability, and customer satisfaction has made them a trusted partner for paper mills around the world.

To learn more about how HEZER Belt can improve your paper production process with high-quality PMC, visit their website at HEZER Belt. You can also explore their story and values in more detail by visiting About Us.