In the industrial world, efficiency, reliability, and durability are critical factors in ensuring high-quality products and consistent performance. Whether you are working in papermaking, drying, or filtration, the quality of the fabrics you use can significantly impact the overall success of your operation. Forming fabrics, dryer fabrics, and filter belts are some of the most essential materials used in various industrial processes, particularly in papermaking, dewatering, and drying applications.

At Hezer, we specialize in providing high-performance forming fabrics, dryer fabrics, and filter belts designed to optimize your production processes. With years of experience and a commitment to excellence, Hezer offers fabrics that ensure enhanced durability, improved efficiency, and significant cost savings. In this blog, we will explore the key features and benefits of forming fabrics, dryer fabrics, and filter belts, explaining why Hezer is the go-to choice for industrial fabrics.

What Are Forming Fabrics, Dryer Fabrics, and Filter Belts?

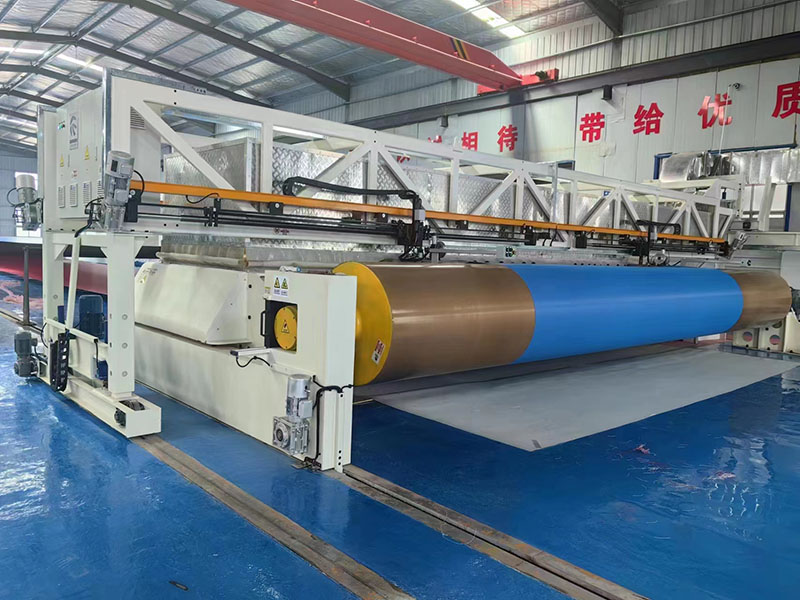

1. Forming Fabrics

Forming fabrics are essential components in the papermaking process. They support and guide the wet paper web during the forming section of the paper machine. Their main role is to assist in the drainage of water, ensuring that the paper sheet forms evenly and with the desired properties. Forming fabrics are typically woven from polyester or nylon materials, providing both strength and flexibility.

2. Dryer Fabrics

Dryer fabrics are used in the drying section of the paper machine. After the paper sheet has passed through the forming section, dryer fabrics help remove the remaining moisture through heat transfer. These fabrics are designed to withstand high temperatures and provide a smooth surface for drying, ensuring uniform moisture removal and high-quality paper production.

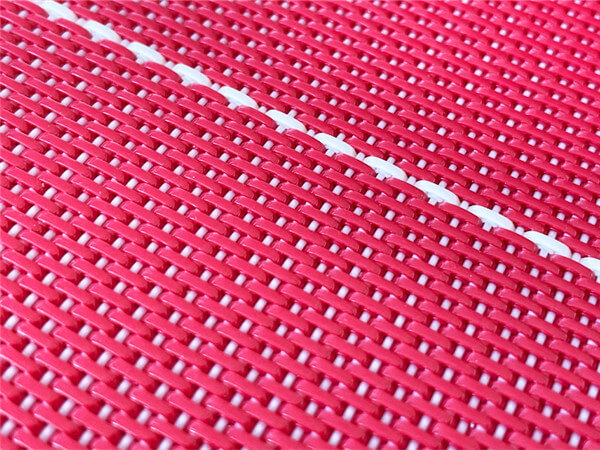

3. Filter Belts

Filter belts are used in filtration and dewatering processes across a wide range of industries. They help separate solids from liquids and ensure efficient dewatering, which is especially important in industries like mining, papermaking, and chemical processing. Filter belts are designed to handle high pressure and demanding conditions, offering high drainage capacity and superior durability.

Key Features of Hezer’s Forming Fabrics, Dryer Fabrics, and Filter Belts

1. Forming Fabrics

Hezer’s forming fabrics are engineered for superior performance in papermaking applications. Key features include:

-

Long Service Life: Designed for durability, our forming fabrics last longer, reducing downtime and replacement costs.

-

Excellent Drainage Efficiency: These fabrics ensure optimal water drainage, improving the efficiency of the paper formation process.

-

High Strength and Flexibility: Hezer’s forming fabrics are made from high-quality materials that offer both strength and flexibility, enabling smooth operations.

-

Wear Resistance: Our fabrics are designed to resist wear and tear, ensuring that they can handle continuous use in demanding conditions.

2. Dryer Fabrics

Hezer’s dryer fabrics provide high efficiency and reliability for drying applications. Key features include:

-

High Heat Resistance: Our dryer fabrics are built to withstand high temperatures, making them ideal for applications in paper drying and other heat-intensive processes.

-

Fast Drying: These fabrics ensure efficient moisture removal, speeding up the drying process and enhancing productivity.

-

Smooth Surface: The smooth surface of Hezer’s dryer fabrics helps prevent defects in the final product, ensuring uniform drying and high-quality output.

-

Operational Reliability: Hezer’s dryer fabrics are designed for long-lasting performance, ensuring operational stability and minimal downtime.

3. Filter Belts

Hezer’s filter belts are designed to excel in filtration and dewatering applications. Key features include:

-

Wear and Tear Resistance: Our filter belts are made to resist abrasion, ensuring long-term durability and reducing the need for frequent replacements.

-

High Filtration Efficiency: Hezer’s filter belts ensure effective separation of solids and liquids, optimizing the filtration process.

-

Fatigue Resistance: These belts are engineered to withstand continuous mechanical stress, providing consistent performance even under high-pressure conditions.

-

Easy Maintenance: With their durable construction and low maintenance requirements, Hezer’s filter belts are designed to minimize downtime and improve operational efficiency.

Benefits of Using Hezer’s Forming Fabrics, Dryer Fabrics, and Filter Belts

1. Improved Efficiency and Productivity

By using Hezer’s forming fabrics, dryer fabrics, and filter belts, you can significantly improve the efficiency of your production process. Our fabrics are designed to optimize water drainage, heat transfer, and filtration, resulting in faster production times, reduced energy consumption, and higher throughput.

2. Enhanced Product Quality

High-quality forming fabrics ensure that the paper sheet forms consistently with minimal defects. Dryer fabrics provide even drying, preventing wrinkles, creases, and other issues that can affect paper quality. Similarly, filter belts ensure cleaner products by effectively separating solids and liquids.

3. Cost Savings

Hezer’s fabrics help reduce operational costs in multiple ways. The long service life and wear resistance of our fabrics reduce the need for frequent replacements, minimizing maintenance costs. Additionally, our dryer fabrics and filter belts contribute to energy savings by improving the efficiency of the drying and filtration processes.

4. Durability and Reliability

Hezer’s forming fabrics, dryer fabrics, and filter belts are built to last. Designed for high-performance applications, they are capable of handling continuous operation under harsh conditions. With superior fatigue resistance and wear resistance, our fabrics ensure reliable performance and long-lasting results.

5. Customization Options

At Hezer, we understand that every industrial application is unique. That’s why we offer customized fabrics to meet your specific needs. Whether you require special dimensions, material types, or performance characteristics, Hezer can provide the right solution for your business.

Comparison Table: Hezer’s Forming Fabrics, Dryer Fabrics, and Filter Belts

| Feature | Forming Fabrics | Dryer Fabrics | Filter Belts |

|---|---|---|---|

| Durability | High | High | Very High |

| Wear Resistance | Excellent | Excellent | Excellent |

| Drainage Efficiency | High | Moderate to High | High |

| Heat Resistance | Moderate | High | Moderate |

| Filtration Efficiency | Moderate | N/A | High |

| Fatigue Resistance | Good | High | Very High |

| Cost-Effectiveness | Good | Very Good | Very Good |

Why Choose Hezer for Your Forming Fabrics, Dryer Fabrics, and Filter Belts?

Hezer is a trusted name in the industrial fabric industry, providing high-quality forming fabrics, dryer fabrics, and filter belts. Our products are designed to meet the unique requirements of various industries, from papermaking to filtration and drying.

Here are a few reasons why Hezer is the preferred choice:

-

Expertise: With years of experience, we understand the specific needs of each industry and offer tailored solutions.

-

Quality: Hezer’s fabrics are made from the finest materials, ensuring high performance and durability.

-

Customization: We offer bespoke solutions for different industrial applications to ensure the best results.

-

Reliability: Our fabrics are known for their exceptional reliability, which means minimal downtime and increased production efficiency.

For more information about our forming fabrics, dryer fabrics, and filter belts, visit our product page.